Introduction

The biggest auto news of 1957 was the introduction of “Ramjet” fuel injection manufactured by GM’s Rochester carburetor division and developed by John Dolza, E.A. Kehoe, Donald Stoltman and Corvette chief engineer Zora Arkus-Duntov. It was optional equipment on the 1957 Corvette engines, and could also be had on V-8’s powering any other Chevrolet car.

The Ramjet was reported to have several advantages: increased power, instant accelerator response, faster cold starts, smoother engine warm-ups, elimination of carburetor icing and better overall fuel economy.

Why Fuel Injection

Chevrolet became actively interested in the GM fuel injection system, primarily for the Corvette, in order to realize the full potential of the engine for high performance. Fuel injection had been used for many years on truck and passenger car diesel engines, and Rochester had developed their version with an eye to make it available for the 1957 model year.

Two types of fuel injection were considered and tested at the GM Tech Center and at Rochester. The “A” type, which was continuous flow injection with the nozzle located directly outside each cylinder, spraying into the intake port, and the “B” type, which was timed injection. The “A” system was developed by the Engineering staff at the GM Tech Center and the “B” by Diesel Equipment Division and the research staff. The “A” system was chosen for earliest release, primarily from a standpoint of simplicity and cost.

Operation

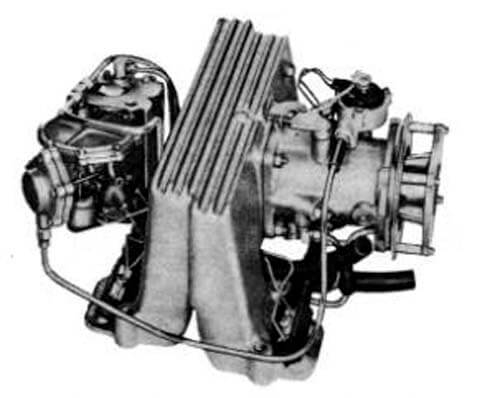

The Rochester fuel injection system has three basic components: the air meter, the fuel meter and the intake manifold. The air meter supplies a control signal to the fuel meter in response to engine load (vacuum in the intake manifold is a measure of how much air is entering the engine). The fuel meter uses the vacuum control signal to regulate the fuel flow to the injection nozzles. The intake manifold provides the distribution system for the rammed airflow to the cylinders.

1957 Units

The first Rochester fuel injection unit was #7014360. Very early units did not have the familiar black Rochester Products I.D. tag, and the unit number (serial) was stamped into the lower front of the plenum vertical face. Early plenums had the “Winters Snowflake” cast in the ribbed area of the plenum.

Early #7014360 units used a dual four-way fuel meter distributor or “spiders” to deliver fuel to the nozzles. Later #7014360 and subsequent units had a single right tube spider. This change took place around 2/1/57. It should be noted that the single spiders used through 1957 and 1959 #7017300 and 7017300R units have lines individually attached by ferrules and nuts. Later spiders are soldered together beginning in 1958. Also early #7014360 units had three designs changes.

The next unit from Rochester for 1957 was the #7014520. It, as well as later #7014360 units, had the black I.D. tag on the plenum. Early #4520 units had a snowflake on top of the plenum. The #7014520 and subsequent units were similar to #7014360, however the control diaphragm vent was relocated from the under side of the fuel meter cover to the outboard surface of the fuel bowl.

Air for the nozzles was taken from a boss on the air meter casting, after the air has passed the venturi. The nozzle air pipes were redesigned to fit this arrangement. The cold enrichment system was completely redesigned, using manifold vacuum as a signal boost rather than using the power enrichment system. Finally, new type nozzles containing an orifice plate and fuel strainer were used.

The third type of unit used in 1957 was #7014800. It was introduced in mid- to late-1957 and was a refinement of the #4520 design. On the 4800, the nozzles were longer and extended into the air stream for better response. Cold enrichment used two valves – one for power diaphragm vacuum and the other for signal boost vacuum. When the car was first started, enrichment was caused by signal boost plus power enrichment. As the engine warmed up, the signal boost valve closed and only power enrichment was used. When the normal operating temperature was reached, the power diaphragm vacuum valve opens and the system reverted to normal driving controls.

1957-58

The fourth and final 1957 unit developed was the #7014960. It was used in late 1957 and carried over into early 1958. The 1957 Rochester units used a microswitch and a solenoid (mounted on the fuel meter) to provide ample fuel during cranking. This was also used on 1959 units #7017300 and 300R. All 1957 units have a rough sand-cast fuel meter.

1959

In 1959, two new units were released, the #7017200 and #7017250. The #7200 and #7250 are very similar to the #4900, and they may be very difficult to tell apart if the model plate is missing. Both of these units had a fuel meter design that incorporated an internal “cast in” siphon breaker to stop the possibility of the fuel flow from the reservoir into the engine cylinders.

The siphon breaker can be found as a protrusion on the side of the fuel meter body closest to the intake manifold. These fuel meters were die cast, as were #4900 meters. This design was continued through 1965 with minor changes.

Also in 1959, some leftover #701480 and #7014960 units were recalibrated by Rochester and the plenum tags were changed to #7017300 or #7017300R and released for 1959 vehicle usage. These used 1957 fuel meters, spiders and cranking enrichment solenoids with a microswitch. On the #7017300, the signal line ends at the fuel meter in a simple elbow connection. These units did not have internal siphon breakers.

The intake manifold adapter was redesigned for 1959, allowing easier distributor removal. The distributor pad was 3/4″ lower using a 3/4″ spacer and gaskets to maintain the proper distributor height. Also, individual inlet manifold gaskets were used for the first time. An air cleaner adapter with the air cleaner element mounted on the radiator support was also changed for 1959.

Identification Tags

The identification tag, which includes the part number and serial number, is riveted to the left side of the manifold at the front corner. The part number is also on a triangular foil tag held by one of the screws attaching the enrichment diaphragm cover.

Air and Fuel Meters

Air meters and fuel meters were normally stamped with the last three digits of the unit number. Earlier units through the 1959 model year may have had all seven digits stamped on a part. For example, a 1958-59 #7014900 would have a 901 stamped on the air meter and a 902 stamped on the fuel meter. The 1959 #7017200 fuel injection unit number has an air meter stamp of #7017201 with a fuel meter stamped 202.

Want your Fuel Injection Unit Serviced? Try:

Ramjets That Run. Jerry Bramlett, Mobile, Alabama

Click on the Images Below to Enlarge

1957-1959 Fuel Injection ID. You may view this Chart by clicking the button below.