Generation One Nash, Hudson, Rambler V8 (1956-1966)

Members of the AMC hobby refer to this engine family as the “GEN-1” AMC V8. It was created more out of necessity than out of design. In 1954, AMC President George W. Mason had made a verbal agreement with Packard that the two companies would supply parts for each other as appropriate. This was based upon ongoing talks about a merger of the two smaller companies. As a show of good faith, AMC started using this agreement to buy Packard V8s in late 1954 for use as the main powerplant for the 1955 Nash Ambassador and the newly acquired line of Hudson Hornets.

In 1955, the engine supplied was the base Packard “Clipper” 320cu. in V8. In 1956 it was the 352cu. in used across the board by Packard. The engine was also supplied with the Packard “Ultramatic” automatic transmissions because the unit that AMC was using for its 6-cylinder cars was not strong enough to handle the Packard’s torque, nor would it bolt to the Packard engine without a new transmission case, a far too expensive tooling operation for such a small amount of vehicles.

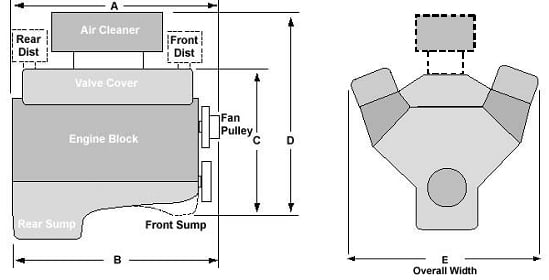

Comparative Size, Dimensions, and External Specifications

The table below shows the Gen 2 and Gen 3 engine external specifications and weights, beginning with 1966 290 V-8 and including all low and high deck blocks, and ending with the 401 V-8. Below is a picture of how to measure to determine and identify the engines. Also enclosed is a chart showing the size and weight of the engines and how to determine the dimensions from the enclosed picture.

AMC Engine Dimensions

| Engine | Displacement | A Length | B Length | C Height | D Height | E Width | Distributor | Sump | Started | Oil Filter | Average Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|

| AMC Gen 1 | 250/287/327 | Varies | 27.75 | 24 | Varies | 24.12 | rear | rear | right | left rear | 601/651 |

| AMC Gen 2 | 290/343/390 | 28.5 | 29.25 | 20.75 | 29. | 21.25 | front | rear | right | right front | 540/600 |

| AMC Gen 3 | 304/360/401 | 28.75 | 29.25 | 21.75 | 29.5 | 21.50 | front | rear | right | right front | 545/605 |

The Generation One V-8s (1956-1966)

Packard’s side of the deal – to buy AMC parts was only handled half-heartedly. They did send AMC some bids, but the responses by AMC were rejected by Packard as “too expensive”, though AMC had dealt with Packard fairly on the pricing, in fact, more so than Packard’s pricing on the V8/transmission deal. Shortly after, Mason passed away and George W. Romney, AMC’s new penny-pinching CEO, spoke out against the merger, which only fueled the fire of an unfair deal. He decided against further relationships with Packard and let it be known that the V8 deal would expire when the contract was over.

Packard told Romney that they intended to end the deal sooner, as they needed their total production for the hot-looking new Packards. An incensed Romney ordered his engineering department to develop an in-house V8 “tomorrow”. The engineering department hired David Potter, a former Kaiser Motors engineer, to come in and help develop the engine. Potter had previously worked on a V8 design for Kaiser and had the experience necessary. Amazingly he took the engine from the drawing board to full production in just under 18 months, an extraordinary engineering feat at the time! This is before CAD/CAM and computers — when hand drawing and slide rules were the norms.

As such, AMC came up with a one size fits all design – one that could go from a small 250 cubic inches to close to 400, though the engine never went beyond 327. All the Gen 1 engines share common external dimensions, weight – about 640 lb, deck height, and bore centers. They all featured�forged crankshaft and rods, most other parts were shared. The stroke for all the Gen 1 V8s was 3.25 inches. Engine displacement was varied by bore alone since it was easier to cast/bore different blocks than to forge multiple crankshafts.

Bore size can be determined as it was cast into the top of the block near the back of the right-bank cylinder head. This is difficult to see with the engine installed in a car due to the proximity of the heater core to the engine. It can be seen, however with a small inspection mirror, a flashlight, and some dexterity.

The 250 Cubic Inch Version

The 250 was AMC’s first home-built V8. It was used in American Motors Corporation automobiles from 1956 through 1961. As the name implies, it had a 250 cu. in. displacement and was a modern overhead-valve, pushrod engine when released. The design made its debut in the Nash Ambassador and Hudson Hornet “Specials” of 1956. These cars had the top-of-the-line Ambassador model trim, but were built on the shorter wheelbase Statesman and Wasp chassis, hence the “Special” name.

The 250 had a 3.50″ bore, 3.25″ stroke, and used solid lifters. It did come in two and four-barrel carburetor varieties, but in year one, it used a 4-barrel only for the Nash/Hudson “Specials”. The 250 was a snappy performer that showed that the engine had good potential. Since it was�designed to be expanded to much larger engine sizes, it was quite sturdy.

The 250 V8 became the optional engine offering for the 57 Rambler, with the Ambassador and Hudson receiving the new and larger 327cu. in version. All 1958-1960 V8 Ramblers were designated as the “Rambler Rebel” and were a separate series from the 6-cylinder models. In 1957, there was also a “Rambler Rebel” special performance model, but it used the 327 V8 and was available for one year only. In 1960 ½the Rambler Six was renamed the “Rambler Classic” to avoid model confusion in the Rambler line-up. A V8 engine then became an option in the Classic instead of a separate model. In 1963 the 287 debuted for Ramblers and was used in 1964 as a Rambler-only option. The 327 stayed exclusive to the Ambassador. For 1965 and 1966 the 287 and 327 were available in both the Classic and Ambassador.

The 287 Cubic Inch Version

In the mid-model year 1963, AMC introduced a 287 cubic inch V8. When the 250 was dropped in 1961, there was no V8 option for Rambler models other than the top-of-the-line Ambassador, which was only available with the 327. Dealers complained so the 287 was introduced as an option for the “mid-size” Rambler. Unlike the 250 and the 327, it used hydraulic valve lifters. It featured a larger 3.75″ bore and the same 3.25″ stroke for the 250. Only 2-barrel carbureted versions were produced, there was never a 4-barrel option from the factory for the 287. This engine was always considered as�the “economy” model V8. The 287 was produced through 1966.

The 327 Cubic Inch Version

The AMC 327 was similar to the 287 but displaced 327 cubic inches because of its bore increase to 4.0 inches. Unlike the 250, the 327�was introduced in 1957 with hydraulic valve lifters.

The 327 was not available in any Rambler models in 1957 other than the Special Edition Rebel. The Nash Ambassador and Hudson Hornet “Special” models were dropped after 1956, replaced by standard wheelbase models with the 327 V8 instead of the 250 V8. The separate big Nash and Hudson cars were dropped after 1957. They were both replaced in 1958 by “Ambassador by Rambler”, which really was a stretched Rambler with the 327 V8 fitted instead of the 250. The 327 was exclusive to the Ambassador line and could not be ordered in a Rebel or Classic through 1964.

The 327 was also sold to Kaiser Motors from 1965 to 1967 for use in the early Wagoneers and the Gladiator pick-ups. Jeep called it the “Vigilante” V8. Kaiser-Jeep switched to Buick 350s in 1967 to power these vehicles. The GM engine was used until 1970 when Jeeps once again were powered by AMC V8s. That year American Motors had acquired the Jeep Division of Kaiser.

There was a low and high-compression version of the 327 starting in 1960. Prior to 1960, all were high compression. All low-compression models used a 2V carburetor and all high-compression models received a 4V carb. The low compression engine used 8.7:1, and the high featured 9.7:1. The compression was set by the piston top design; all the heads were identical.

1957 327 Rambler “Rebel”

This engine debuted in a special edition Rambler called the “Rebel” Only 1500 Rebels were made. All had silver paint with a gold-anodized “spear” on each side. This was to be the first electronic fuel-injected (EFI) production engine, but teething problems with the Bendix “Electrojector” unit meant that only a few engineering and press cars were built, estimated to be no more than six units. (This unit was also to be used on the new model Chrysler 300, which had the same problems – though some were delivered with the unit). Â This 327 had a high lift, longer duration mechanical lifter camshaft, special assembly, and other features; it was not just an Ambassador 327 stuffed in a Rambler.

At least two Rebels with EFI are known to have been built. One was sent to Daytona Beach, Florida for “Speed Week” (the forerunner of today’s Daytona 500). It was the second fastest car on the beach, bested only by a 1957 Chevrolet Corvette with mechanical fuel injection, and only by a couple of tenths of a second.

The EFI 327 was rated at 288 hp, and the production unit, which used a 4-barrel carburetor, at 255 hp. All the existing EFI cars were converted to 4V carb before being sold; none are known to have existed outside the engineering department at AMC. The problem with the Bendix EFI was that the electronics of the time (vacuum tube and transistor) were susceptible to radio interference and impacted by heat. When it worked, it worked great.

Ironically, Bendix licensed patents based on the 1957 design (in a patent dated 1960) to the German firm Bosch, who perfected it as the basis for their D-Jetronic injections system, first used in 1967. By that time electronics had taken a huge step forward in miniaturization and reliability. Obviously, the 1957 Rebel (and EFI) were just too far ahead of their time.

Regardless, even with a 4-barrel carb, the Rebel was a performer. Those who tested even the non-EFI car were amazed by its performance. In actuality, AMC had scooped the idea of the muscle car by seven years by using the concept of a big engine in a lighter, mid-sized car – and it worked. The problem was George Romney, who saw the Rebel as a marketing exercise for the 327 V8, but not a true production model. After 57, the 327 stayed in the Ambassador in a detuned format, never to relive its potential greatness.