Olds Gen 2 Small & Big Block Engines

1964-1990: General

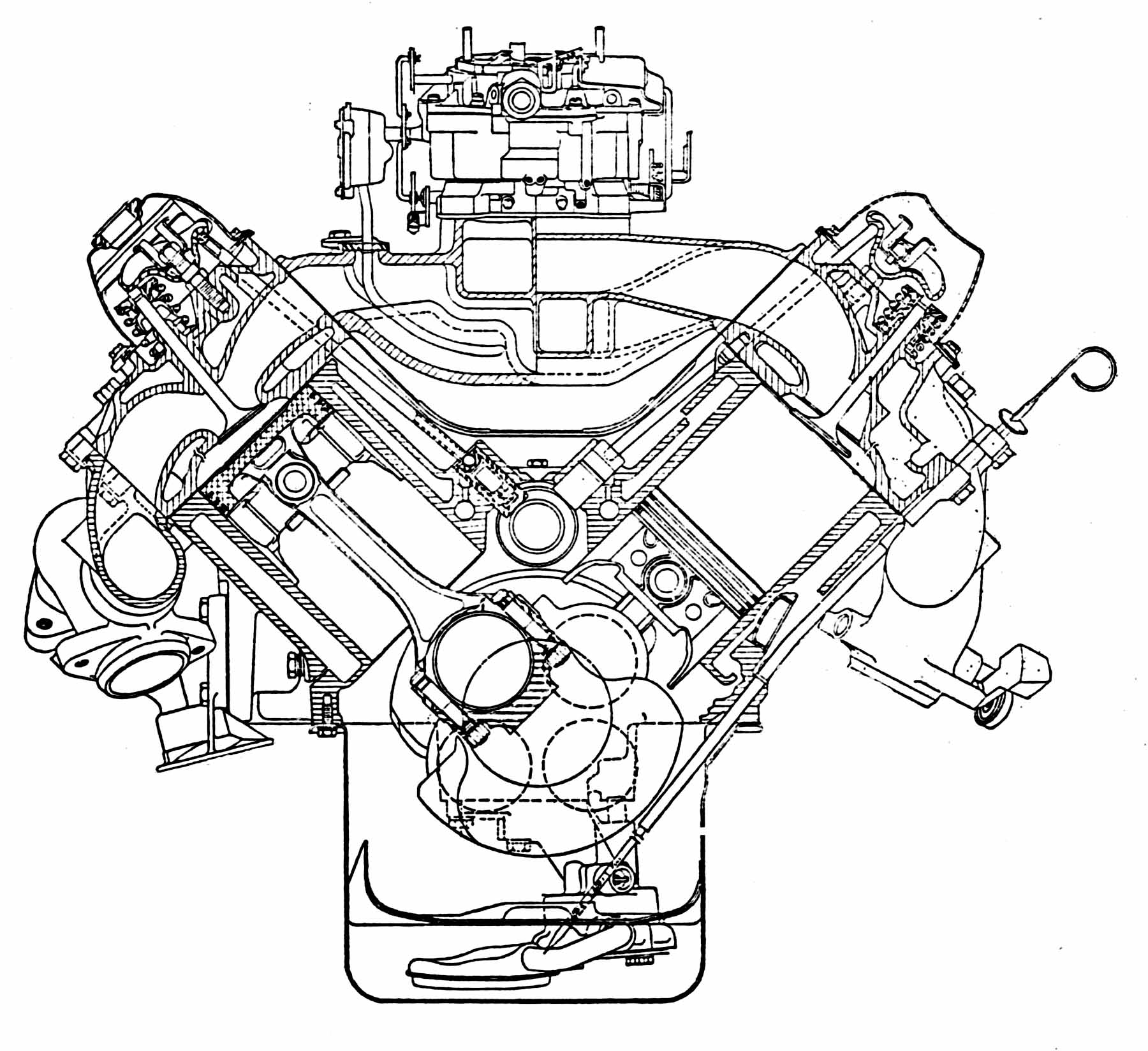

All Oldsmobile small and big blocks used the same critical dimensions, using the same bore centers, although “big-block” versions were produced with a 10.625″ deck height rather than the 9.33″height of the small block. Big-block and Diesel versions also used a larger 3.0″ main bearing journal instead of the 2.5″ mains of the small block. All generation-2 small-block Olds V8s used a stroke of 3.385;” however, the big-block used either a 3.985″ (1965-1967) or a 4.25″ stroke (1968- 1977).

Generation 2 engines, while being a wedge-head design, had a unique combustion chamber that resulted from a valve angle of only 6 degrees. This was much flatter than the 23 degree head of the small-block Chevrolet and 20 degree head of the Ford small-block wedge. This very open and flat chamber was fuel efficient and had lower than average emissions output. It was the only GM engine to meet US emission standards using a carburetor – all the way up to 1990, when it was finally retired.

All Oldsmobile engines used hydraulic lifters, including the high performance versions.

Small Block – General History

In 1964 Olds replaced their small block 215 V8 with a cast iron block of completely new design. The 330 V-8 shared none of its engine block architecture with that of the 215 V-8 and the 225 V-6 sourced from Buick. The engine was no longer aluminum, but cast iron, as weight became less of a factor with the engine going into both the larger mid-sized F-85s and Cutlasses as well as the full-size Jetstar 88s introduced in that year. It was also to be used as the workhorse for the entry-level full sized vehicles. The horsepower and torque of the 330 allowed for the engine to be installed in the full-sized Jetstars as the base engine, In 4-barrel form, it would be the upscale powerplant for both mid and full size Oldsmobiles. In 1968, the engine was enlarged to 350 cubic inches and again used in 2-barrel and 4-barrel form from that year until it was discontinued in the early 80’s.

The small block was later expanded to 403 cubic inches and also “de-bored” to both 260 and 305 cubic inches in response to tightening EPA mileage demands and smaller body styles. The 305 was modified to be used in the G-Body Hurst/Olds and 442 models, and, given the times, developed more respectible horsepower and performance.

Big Block – General History

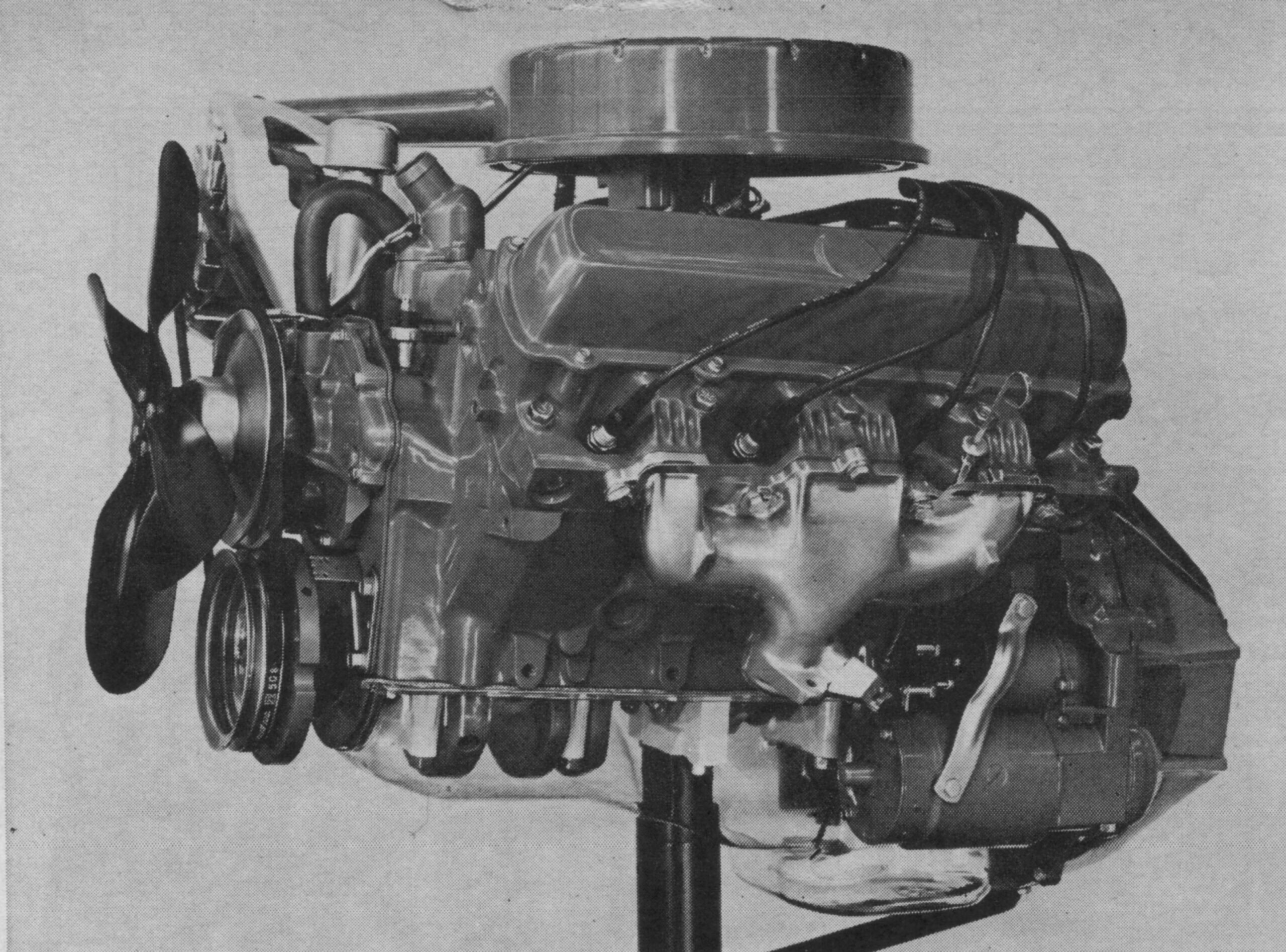

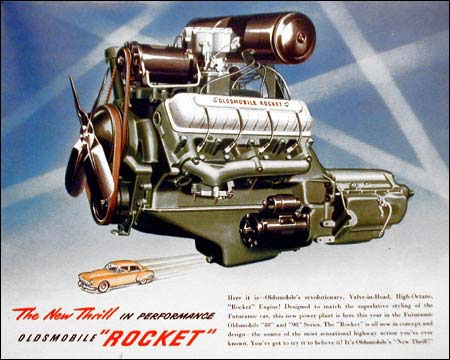

The 400-455 “big block” is really the second generation modern Olds V8, with the Generation 1 engine being the “Rocket” introduced in 1949 and used through 1964. The 1965-1976 big block will be called the “Gen 2 Big Block” here to differentiate between the original big block Rocket V8.

The concept of the big block, as introduced in 1965, was to recast the new small block with a higher deck to allow a longer stroke. Obviously, certain changes were made to accommodate the higher loads that would be faced with the additional power and torque. Thus, though the block is considered a “thin wall” design, it is really not, although design factors did allow it to be about 50 lbs lighter than the 324-394 Gen 1 “Rocket” engine.

The big block was offered in 400, 425, and 455 cubic inch versions, with the original 400 engine replaced by a long stroke, small bore model in 1968. This engine was only available in the Cutlass line and was discontinued for the 1970 model year.

The big block was a good high performance engine, given it was designed as a prime mover for 88s and 98s. As a 400 and 455, it was the performance engine in 442s, Starfires, 88s, and even in the Toronado. By 1973, it began to be emasculated, and the 442 and Hurst cars offered from that date onward were merely warmed over 98 engines. The Big Block lived on through 1976 as the prime mover for Olds big cars, though after 1974, it was detuned and delivered moderate horsepower at lazy rpms.

1964-1967: 330 Cubic Inch V8

The first Generation 2 Olds V8 was the 1964 330 cubic inch engine. It introduced the standard 3.385″ stroke that was used by all Gen 2 Oldsmobile small block engines, including the Diesel, from inception until demise. The 330 used a 3.938″ bore. All small blocks were designed to be machined on the same line as the big block so, other than the deck height, the bore centers were the same.

All 330s had forged steel crankshafts, forged connecting rods, and cast aluminum pistons. The 4 barrel versions used a harmonic balancer while the 2 barrel made do without one. The 330 utilized a 1.875″ intake vale and a 1.562″ exhaust valve. Compression ratios varied from 9.00:1 to 10.25:1 by varying the piston dish.

Horsepower ranged from 245 to 320 and torque from 335 to 360 ft. lbs. This was accomplished by a combination of camshaft timing, compression ratio, and carburetor size.

The 330 was fitted to all Oldsmobile body sizes, including the Cutlass, Jetstar 88, and Delta 88.

1965-1967: 400 Cubic Inch V8

The 400 cu. in. big block was was the second tall-deck “big-block” Olds introduced to power the 442. This engine was not forseen, but was manufactured because GM had mandated a 400 cu. in. limitation on mid-size cars. The 400 was constructed by limiting the bore of the larger 425 block to 4.000″.

The result was that the 1965 through 1967 (early) 400s had a slightly over-square 4.000″ bore and 3.975″ stroke. Though an “accident,” this motor became a solid performer that could easily be made to develop over 400 HP when modified.

Horsepower ranged from 300 (2-barrel Turnpike Cruiser) to 360 (three 2-barrel W-30) and torque from 425 to 440 ft. lbs. This was accomplished by a combination of camshaft timing, compression ratio, and carburetor size.

The 400 was fitted only to the Cutlass and 442 series vehicles.

1968 – 1976: 350 Cubic Inch V8

Produced from 1968 through 1980, the 350 cubic inch V8 used a 4.060″ bore and the Oldsmobile small-block standard 3.385″ stroke to reach 350 cubic inches. In a change to reduce costs, the 350 utilized a cast nodular iron crankshaft in place of the 330’s forged unit.

The Oldsmobile 350s made from 1968 through 1976 are more desirable as they had heavier block castings, beefier crankshafts, and better flowing heads. Engines produced after 1976 utilized true thin-wall castings and lost reinforcement in the main bearing saddles. They should not be considered for high performance modification.

The standard 350 utilized a 1.875″ intake vale and a 1.562″ exhaust valve in the period from 1968 to 1972. In 1971 and 1972, the exhaust valve seats were changed to utilize stainless steel inserts to allow unleaded gasoline usage. In 1973 the standard 350 utilized a 1.625″ exhaust valve and a different head casting not suitable for performance work. Compression ratios varied from 8.50:1 to 10.50:1 by varying the piston dish, and, from 1973 on, by varying the combustion chamber size.

1977 – 1980: 350 Cubic Inch “R” V8

The 1977 thru 1980 350 had the “lightweight” castings, including a thinner block with large “windows” in the main bearing bulkheads, crack-prone head castings which were actually manufactured by Pontiac (castings are marked “PMD” and should be avoided); and a lightened crankshaft. The R version was the first “corporate” engine offerings and was made available to Buick, Pontiac, and Cadillac for their mid- and large-sized models. Chevrolet full-size wagons were also equipped with this engine. The 350 R was popular because of its ability to meet emissions requirements even with a carburetor. The Oldsmobile 350 R was also produced with an analog electronic port fuel injection system, introduced in the Cadillac Seville of 1976, and was only moderately successful.

1979 – 1980 L34 350 Cubic Inch V8

Oldsmobile’s L34 350 V8 was used in the 1979 and 1980 Hurst/Olds models and was a throwback to the engine produced between 1968 and 1976 in that it was not a lightweight casting. The L34 used a 4-barrel carburetor and produced 160 to 170 hp and 275 ft. lbs. of torque.

1978 – 1985 LF9 350 Cubic Inch Diesel V8

The LF9 Diesel V8 was produced from 1978 to 1985. The 1978-1980 “early” block is identified by a “D” cast into both sides. This block is weaker than later designs. The 1981-1985 had an improved block, with the main bearing saddles reinforced and the casting increased in critical areas such as in the head surface and cylinder bore area. These are identified by “DX” cast into both sides of block and should be used in rebuilding a diesel and for high performance applications.

Early diesels made 120 hp and 220 lbs. ft. of torque. Later engines were downgraded to 105 hp and 205 lbs. ft. When used in 1978-1980 GMC and Chevrolet light trucks, it was rated at 125 hp and 225 lbs. ft of torque.The EGR system was cast into the block as was the provision for fuel injectors and when combined with the 3.0″ main journals making this block much different than a standard 350s. The diesel also featured roller lifters, a feature that was carried over to the 305 V8 when released in its second iteration.