1960-1965 Rochester Fuel Injection Evolution and Identification by Year

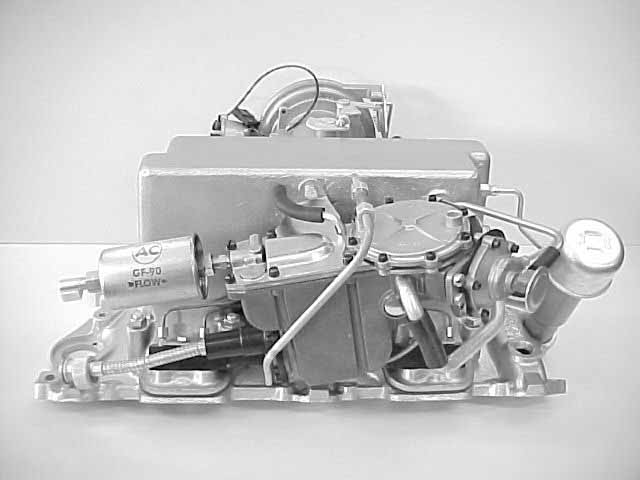

This example is 1960-1962 7017360 “flat top” fuel injection unit.

This is an example of a ’63 – ’65 7017375R fuel injection unit.

1960-61

The #7017200 and #7017250 units used in 1961 were carried over from the 1960 model year. 1960 250HP and 1961 275HP engines used #7017200 units, and 1960 290HP and 1961 315HP engines (some possible) used units #7017250.

In late 1960 a newer plenum design with improved airflow was introduced. This unit had a smooth top with no ribs and was #7017320. This continued through 1961 on high-horsepower cars. The air meter and fuel meter on this unit are the same as in #7017250.

All 1960 and later units had internal siphon breakers in the fuel meters. The choke for 1957-61 units was mounted on the top of the air meter near the Venturi signal passage.

In 1961, a #7017310 unit with a smooth top plenum was released for 275HP cars. This unit is very scarce today.

1962

Beginning with the 1962-model year, no low-horsepower fuel injection options were offered. Two new fuel injection units, the #7017355 and the #7017360, were used on RPO 582, the 360-horsepower engine option. These fuel injection units differed from previous models primarily in the design of the cold enrichment system.

The newly designed cold enrichment and diffuser cone assembly incorporated an almost conventional blade-type choke valve which eliminated the complex valving of cold enrichment systems found in previous models. The electrically heated thermostatic coil, mounted on the air meter inlet, now positioned this choke valve to provide the necessary venturi signal “boost” for fuel enrichment.

The fuel meter design was unchanged except for a redesign of the metering valve, the use of a poppet-type valve in place of the spill plunger, and the relocation of the cranking signal valve to the cover of the power enrichment diaphragm. With the newly designed cold enrichment housing, a vacuum for power enrichment was now drawn directly from the injector intake manifold. The new location of the cranking signal valve virtually eliminated the possibility of its failure due to backfire.

The primary difference between the #7017355 and the #7010360 fuel injection units was a replaceable element fuel filter used on the #7017355, while the #7017360 unit used a throw-away canister type fuel filter. Both of these units have the smooth top plenum design from the #7320 unit.

1963

The Rochester fuel injection unit was redesigned for 1963 with a larger and wider removable top plenum cover embossed with a crossed flag emblem.

The air meter was substantially shorter in length, though the choke setup was similar in design to the 1962 unit. The 1963 unit used a two-line system with a cranking signal valve and a built-in siphon breaker. The spider was also redesigned.

1964-65

The early 1964 design #7017375R was a recalibrated 1963 unit set up for use with the new 1964 camshaft and larger-valved cylinder heads.

The two-line system with a cranking signal valve was replaced later with a one-line system without a cranking signal valve. This unit number was #7017380. For cranking enrichment, a micro switch and a fuel bypass solenoid were used. The solenoid was in-line between the fuel meter fuel inlet and the fuel spider and provided extra fuel at engine supply pressure directly to the nozzles.

Most 1965 units had the vehicle VIN number stamped on the passenger side rear vertical face of the plenum. All 1965 units were mounted on an aluminum fuel injection base plate (casting number #3826810).

Issues

The Rochester fuel injection system had evolved steadily since its inception in 1957 and had become quite reliable when it was canceled in 1965. There were several reasons for its demise, the primary being the introduction of the new Mark IV 396 cubic-inch engine.

The big block offered more horsepower and torque than the fuel-injected small block and was substantially cheaper. Additionally, fuel injection had always suffered in popularity because Chevrolet Service personnel didn’t like or understand the system, a problem recognized from the very beginning.

One Rochester engineer wrote in 1956, “One very important aspect, in fact, the one in which we are most concerned with, is the servicing of these units. It is a foregone conclusion that any new product can be no better in the field than the service that is performed upon it. I believe that the system is basically simple enough that service will be more a matter of training than anything else.”

Unfortunately, many times the Rochester fuel injection unit was replaced with carburetors by frustrated mechanics and used as Service Department doorstops.

Identification Tag

The identification tag, which includes the part number and serial number, is riveted to the left side of the manifold at the front corner. The part number is also on a triangular foil tag retained by one of the screws attaching the enrichment diaphragm cover.

Air and Fuel Meter ID

Air meters and fuel meters were normally stamped with the last three digits of the unit number. Earlier units through the 1959 model year may have had all seven digits stamped on a part. For example, a 1958-59 #7014900 would have a 901 stamped on the air meter, and a 902 stamped on the fuel meter.

The 1959 #7017200 fuel injection unit number has an air meter stamp of #7017201 with a fuel meter stamped 202. Most 1962 and all 1963-65 air and fuel meters were no longer stamped as described above. Some early 1962 fuel meters may have a 252 stamp. On 1965 units, the air and fuel meters were not stamped with a portion of the unit number, as earlier units had been. Some units have the first four digits of the part number omitted.

Want your Fuel Injection Unit Serviced? Try Ramjets That Run. Jerry Bramlett, Mobile, Alabama