by Society Staff –

Reprint with Permission Only

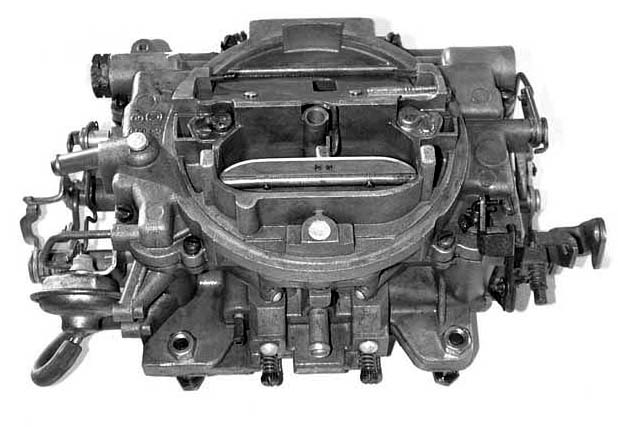

The Carter AVS (Air Valve Secondary) is a refinement of the basic AFB design. Whereas the AFB used a velocity valve, which is a counterweighted flap below the secondary venturi, the AVS used an air valve, which is a spring-loaded flap above the venturi. The purpose of the two is similar, but the air valve is adjustable from outside the carb.

Carter AVS carbs appeared in 1966 on the 275 HP version of the Chevrolet 327, but were never again used on Chevys after that. AVS carbs were found mostly on MOPAR applications from 1968-1971. The most sought-after AVS carbs are the 800 CFM models found on 440 CID motors.

Recently, Edelbrock has been marketing the Thunder Series AVS carburetor, again reproduced by Weber USA. Carter did not build a performance version of the AVS after OEM production in the 1971 model year.

The AVS operates similarly to the Quadrajet and ThermoQuad, except that the secondaries are not as large as in those carbs. When the throttle is opened so that the secondary throttle plates begin to open, a vacuum develops under the air valve, slowly pulling it open. In this way, the air flow is controlled and the mixture is kept from getting too lean if the throttle is opened suddenly.

Carter AVS carburetor – OEM 1970 340 MOPAR unit

Edelbrock AVS carburetor – 650 CFM unit shown

The AVS carb was quite a departure from the convention at the time of its introduction. The counterweighted velocity valve of the AFB was scrapped, and a spring-loaded air door was fitted at the top of the carb. Positioned above the fuel-discharge point, the air valve created a depression or low-pressure area at the fuel-discharge point. This dramatically increased the reaction rate of the secondary fuel circuit.

The system was so effective that a conventional booster venturi wasn’t needed, and AVS carbs were fitted with fuel spray bars, which complemented the air valve perfectly. The spring-loaded air door was easily adjustable for opening rate by simply loosening a lock screw and winding the spring tension on the valve’s shaft.

AVS carbs came in two basic sizes. The differences are the primary throttle bores and venturi sizes. MOPAR 340 and 383 carbs used 1-7/16 inch primary bores and a 13/16 inch venturi, while MOPAR 440 carbs featured 1-11/16 inch primaries and a 1-7/16 inch venturi. Both had 1-11/16 inch secondaries. The difference is clearly seen below. AVS carbs were not rated for airflow, but similarly sized AFB carbs were rated at 625 and 750 CFM respectively.

Like the AFB carb, the AVS is simple in construction, with only two major castings: a main body that incorporates the throttle plates, bores, and float bowls, and the cap with a separate air-horn casting that mounts the floats and fuel inlet system. One of the main distinguishing characteristics of the AVS is the fuel-metering arrangement.

Up front, the primaries are similar to the AFB, where one finds a conventional booster venturi at the fuel-discharge nozzles – these bolt into the main casting. In the rear, an AVS departs from the AFB design, with the carb-metering fuel via spray bars.

The air horn has a minimum of parts: the floats, needle and seats, fuel inlet, and idle vent, if so equipped. A plunger-type accelerator pump is also mounted to the air horn and retained by a special pivot screw.

Original AVS carbs use three-step metering rods with corresponding jets. These are no longer available as tuning parts, whereas AFB rods and jets are commonly available. The difference is the AVS three-step rods are longer, and the jets are deeper. The AVS top cover is also raised for the required space. Substituting a flat AFB metering-rod cover will allow common AFB rods and jets to be used. The metering-rod springs will interchange, and the AFB accelerator-pump squirters can be used if the forward edge is ground to the AVS profile.

Edelbrock www.edelbrock.com AVS carbs are available in 550, 650, and 850 CFM configurations. Edelbrock also offers springs, jets, rods, and calibration kits that may fit older AVS and AFBs.