One of the most enjoyable visits the staff of No Limits Magazine had during the 2013 SEMA MPMC Media Trade conference was our visit with Steve Raymond, General Manager of DynoTech Engineering. Dynotech Engineering Service builds custom Racing Driveshafts, Hotrod Driveshafts, Muscle Car Driveshafts, and Four Wheel Driveshafts for almost all applications. All of their driveshafts are hand assembled, computer welded, and high-speed balanced to the best standards in the industry.

DynoTech is the racing driveshaft manufacturer of choice for teams in the following sanctioned bodies: NASCAR Sprint Cup & Nationwide Series, Craftsman Truck Series, NHRA, IHRA, SCCA NSCA, NMRA, APBA, and OSS.

That in and of itself would be noteworthy, but what was truly an eye-opener was when Steve told me that a custom steel driveshaft could be ordered for as little as $360 and an aluminum shaft starting at $ 460. DynoTech’s driveshafts include the front yoke and rear flange/yoke with U-joints. All of their shafts are built with:

- U-joint clearance to less than 0.002″.

- Shaft runout to less than 0.010″.

- Balanced to less than 0.20 oz-in

- To within 1/16″ (.0625″), guaranteed to fit!

- Balanced most shafts at up to 8,000 RPM

All that AND FREE SHIPPING !!

For those of us who have restored an older car, swapped engines, or built a hot rod, you could not go out and buy a used driveshaft, have it cut to size and the yokes welded back and balanced for anywhere close to these prices, And you still have a used driveshaft.

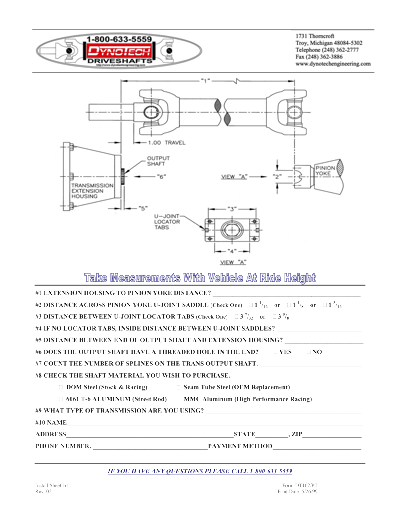

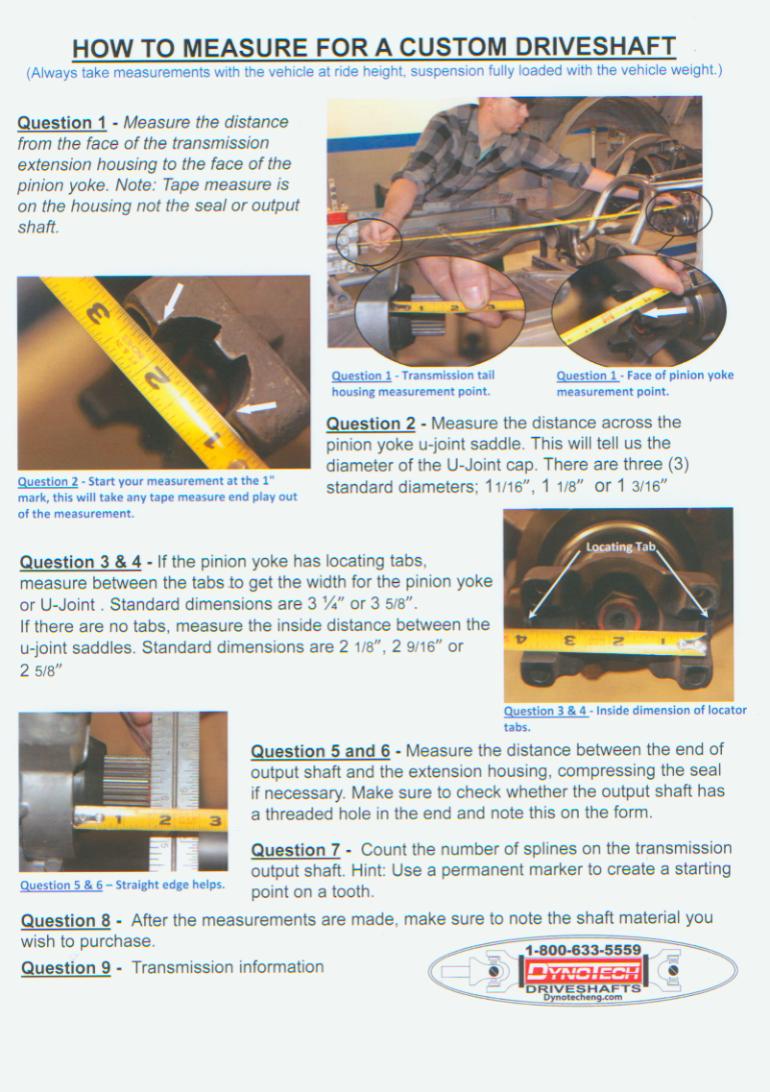

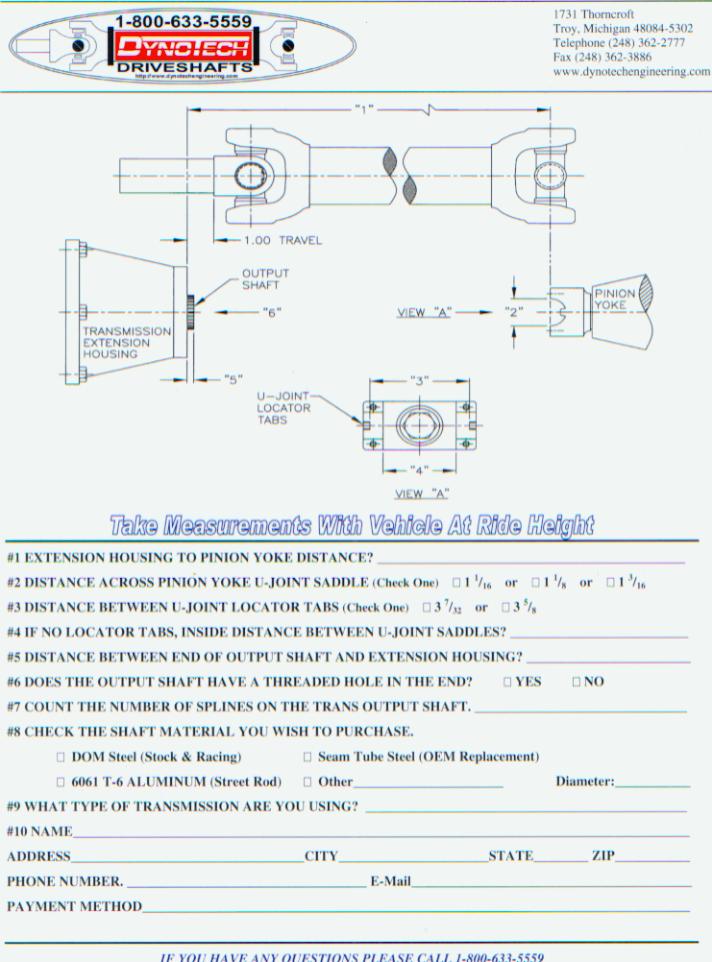

DynoTech engineering has a simple-to-understand order form that details the measurements and information needed to order your driveshaft.

Steve showed a video of the entire manufacturing process. The tubes are cut and the ends are trued and beveled for a precise fit of flanges and yokes. The welds are done so perfectly that they look like part of the shaft (note — I wish I could weld half as good as that !). Each shaft is then balanced — up to 8,000 RPM — to within a 1/8 oz. in. What that means is that the shaft is true and without any bad vibes at higher RPM levels.

As the owner and restorer of two 60’s cars and a custom V8 240Z, I lusted after DynoTech’s shafts. So, if you need a driveshaft, don’t fool with used parts — give Steve a call and tell him that No Limits Magazine and Automotive History Preservation Society sent you. You won’t be disappointed

Dynotech Engineering www.dynotechengineering.com

Measurement Worksheet

Driveshaft to Flange

Measurement Worksheet

Driveshaft to Yoke

DynoTech driveshaft — a thing of beauty

This is how to measure correctly for your custom driveshaft

DynoTech Engineering Order Form