We can look back at the forty-plus years that the 221-351 Ford V8 was installed in cars – not to mention that you can still buy one as a crate engine even today and marvel at how versatile the compact design was – powering everything from a mundane Ford sedan to an Indianapolis race car.

But how did it come about, and why did it reach such popularity? In this article, we intend to talk about the how – later on we’ll address its successes and iterations.

First, we should remember that Ford already had a “small block”; the 234-312 “Y-Block”. A few things worked against this tried and true V8; one, it was heavy, weighing in at over 600 lbs; and two, the cylinder heads were not state of the art – and were limited in their breathing. Second, dimensionally, it was as large as many “big block” V8s of the era, making fitment in Ford’s planned “mid-size” Fairlane and Meteor impractical.

Thus, their design parameters resulted in not only a light weight and compact V8, but they were determined to make it sturdy and very reliable. Larger than necessary main bearings were designed in ostensibly because they had removed the deep block surrounding the mains to save weight, they needed a short stroke to keep the deck height low, so the engine would not be wide, and to ensure no hot spots in the head, they went to the IEIEIEIE valve placement. To reduce costs they utilized a similar rocker arm design to Chevrolet and Pontiac, which was also lighter in weight.

Assuming the engine would grow in size right from the outset, they placed the bore centers far enough apart to allow a 4.0” bore. The stroke was short, due to the engine’s height, also lowering piston speed. The result was a compact, lightweight engine that had great HP potential. As mentioned it took advantage of “thinwall-casting” (pioneered in the Ford Falcon I-6). It was 24” wide, 29” long, and 27.5” tall. And weighed only 470 lb dry in spite its cast iron construction, making it the lightest and most compact V8 engines of its time.

The engine debuted in the 1962 Ford Fairlane and Mercury Meteor at 221 cubic inches (the same size as original Flathead V8) making a modest 143 HP, and it gave the cars peppy performance. Ford realized, however, that were the engine to replace the 292-312 Y-Block across the board, more cubes would be needed. A 260 cubic inch version was released mid-year 1962; followed with a Hi-Po 260 in early 1963. In late 1963 the 289 cubic inch version was released for 1964 model Ford cars. At the same time the famous “K-Code” Hi-Po 289 was offered, carrying over most of the components in the 260 Hi-Po.

The 289 carried the standard of the small block until 1968. When the 302 cu. in version was released. The 302’s architecture remained the same until the pushrod V8 was replaced with the “Modular” OHC V8 in the mid 90’s.

The 221-302 was and is still called the “Windsor” V8 because the original engines were produced in Windsor Ontario, Canada. After 1968, most were produced in the Cleveland engine plant, but because the special canted valve small block originated from there, they continued to be called Windsors until they were no longer produced. The 302 remained in production in Ford products through 2001, and is still available to this day as a crate engine.

Here is breakdown of the various Small Block Fords through 1968:

The 221 was introduced for the 1962 model year as an option on the Ford Fairlane and Mercury Meteor. It had a displacement of 221 cu in, via a 3.5” bore and 2.87” stroke. All of the 1962 through 1964 221-289 engines used a five-bolt bell housing, however, the block mount pads varied in length between the 221 and the 260-289 motors which required different motor mounts to be used when fitted in these earlier cars.

In stock form the 221 used a two-barrel carburetor and a compression ratio of 8.7:1, allowing the use of regular-grade gasoline. Valve diameters were 1.59” for the intake and 1.388” for the exhaust. It was rated 143-145 hp at 4,400 rpm and 216 ft-lbs at 2,200 rpm. The 221 was dropped after the 1963 model year.

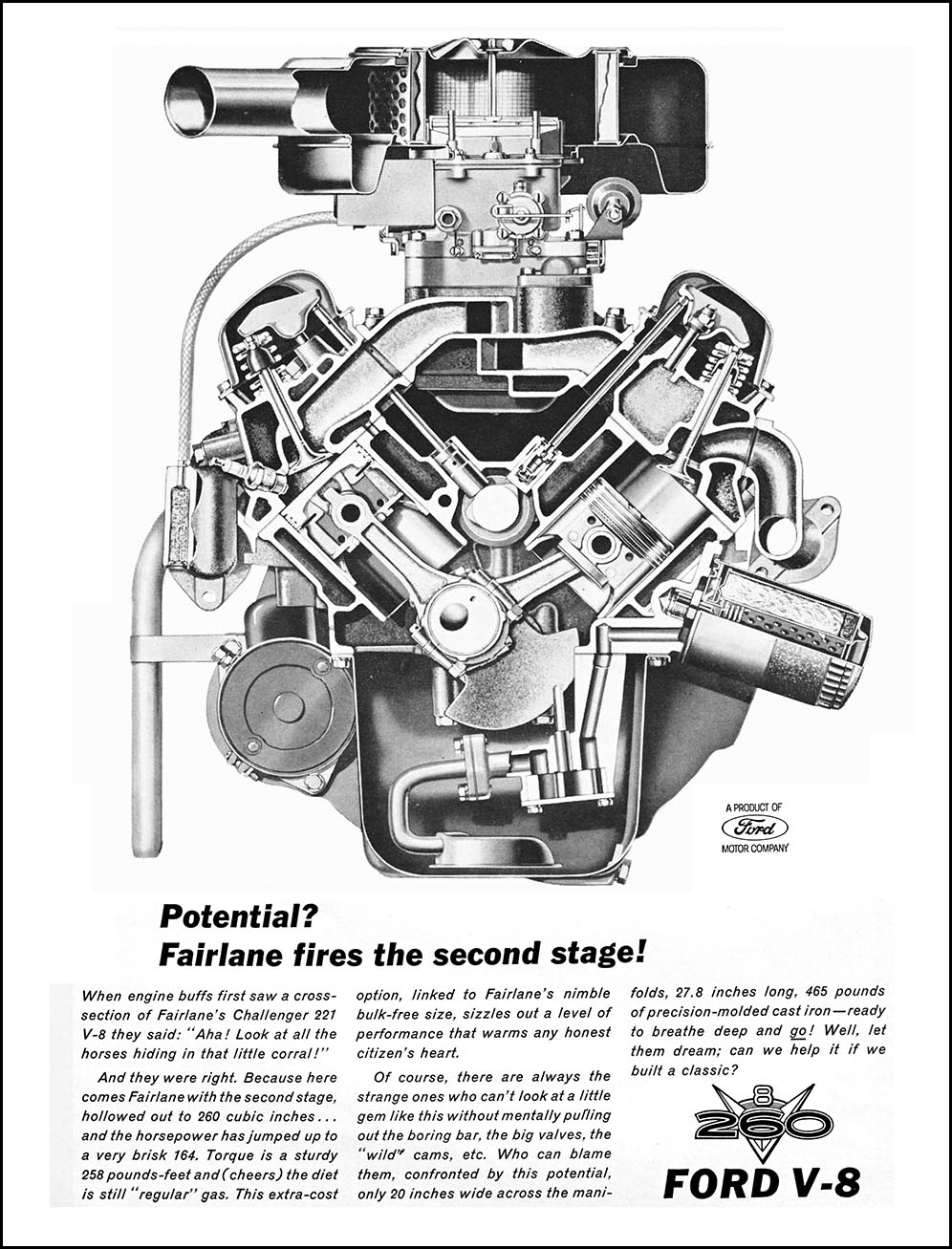

The 260-second version of the Windsor, introduced during the middle of the 1962 model year, had a larger bore of 3.80″, increasing displacement to 260 cu in. The compression ratio was raised fractionally to 8.8:1. The engine was slightly heavier than the 221, at 482 lb. Rated power rose to 164 hp @ 4400 rpm, with a peak torque of 258 ft lbs of torque @ 2200 rpm. In 1962 and 1963, valve diameters remained the same as the 221. Starting in 1964 they were enlarged to 1.67″ (intake) and 1.45″ (exhaust). The rated power was not changed.

In 1963 the 260 became the base engine on full-size Ford sedans. Later in the model year, its availability was expanded to the Ford Falcon and Mercury Comet. The early “1964½” Ford Mustang also offered the 260, although it was dropped by mid-year, It was also the 1964-1966 Sunbeam Tiger Mk I’s engine.

This engine was also the basis of the Indy “stock block” V8 raced at Indianapolis in May of 1963.

The special rally version of the Falcon and Comet and the early Shelby Cobra used a high-performance version of the 260 with higher compression, hotter camshaft timing, and a four-barrel carburetor. This engine was rated at 260 hp @ 5800 rpm and 269 ft lbs of torque @ 4800 rpm. Ford dropped the 260 in favor of the 289 after the 1964 model year.

The 289 cu in version was also introduced in 1963. Bore was expanded to 4.0″. The 289 weighed 506 lb (230 kg). In 1963, the 289 was available in two forms; the base version with a two-barrel carburetor and 8.7:1 compression was rated at 195 hp @ 4,400 rpm and 258 ft lbs of torque @ 2,200 rpm. The two-barrel 289 replaced the 260 as the base V8 for full-sized Fords.

In 1964, an intermediate-performance version of the engine was introduced with a four-barrel carburetor (480 CFM) and 9.0:1 compression and rated at 210 hp @ 4,400 rpm and 300 ft-lbs of torque @ 2,800 rpm. The engine was an option on both the initial 1964 1/2 Ford Mustang and the Mercury Comet. The engine was known as the “D-code” from the letter code used to identify the engine in the VIN.

The D-code engine is rare, as it was only offered as an optional engine in the latter half of the 1964 model year. Both the 1963 and 1964 versions had a five-bolt bell housing pattern that was different from later six-bolt units (Mustangs switched bolt patterns on August 3, 1964). The engines switched from a generator to an alternator in the latter part of the 1964 model year as well.

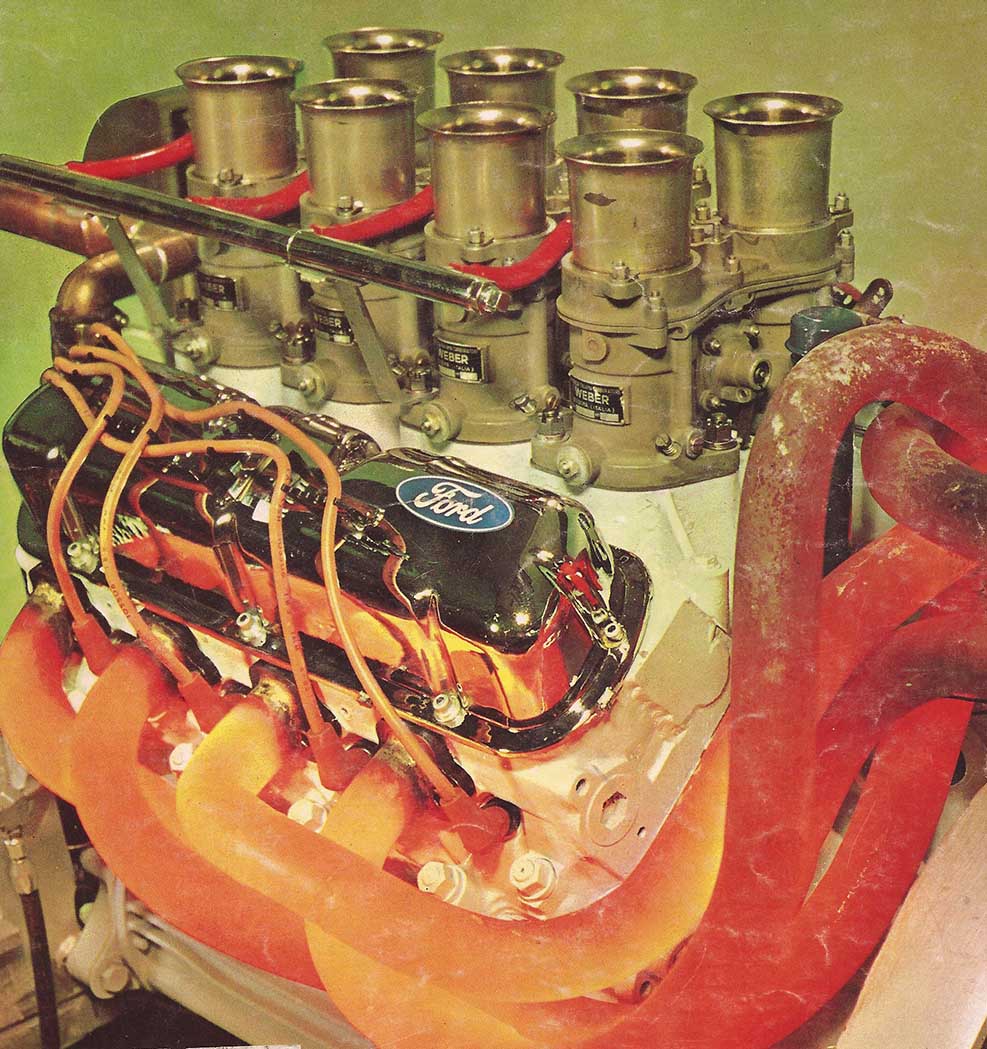

Fords Amazing Small block Image1

Ford Used a “stock block” 260 V8 (highly modified) in the 1963 Indy 500. Here it is at full song on the dyno.

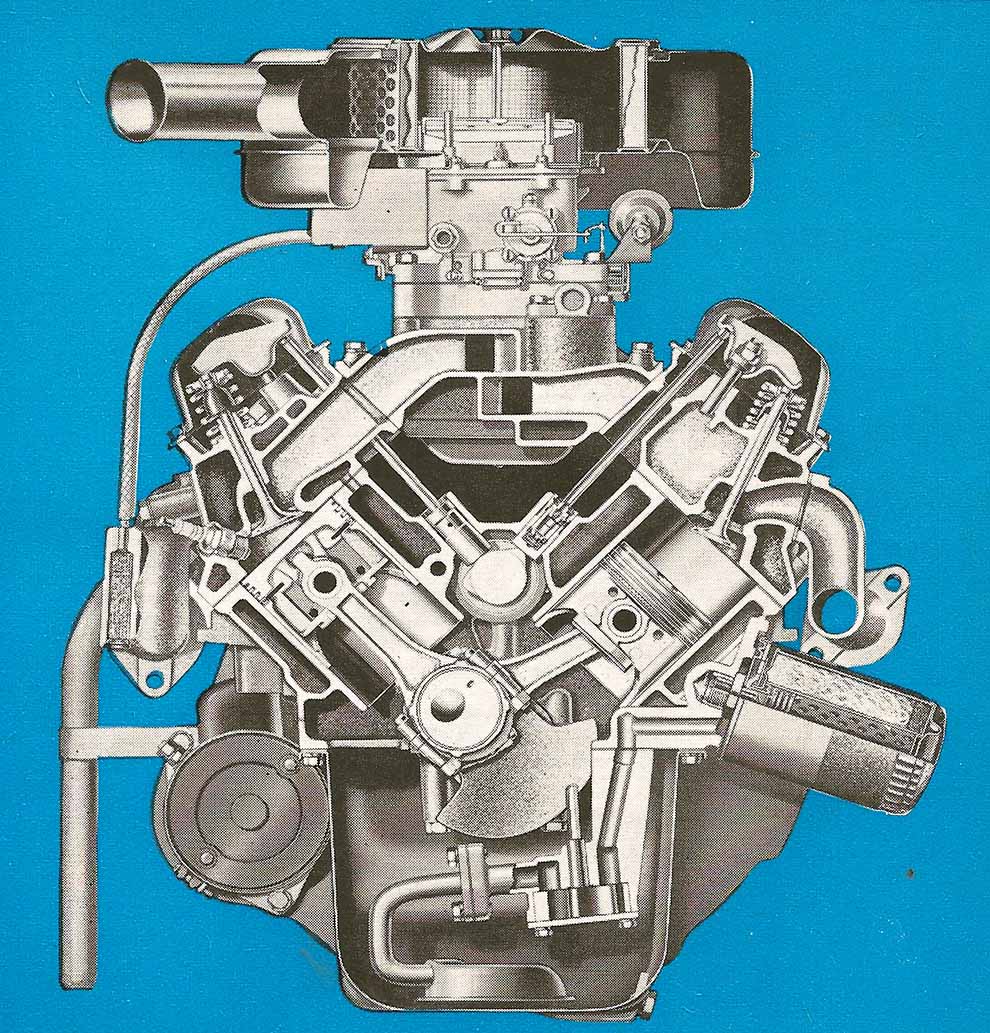

Fords Amazing Small block Image2

A cutaway of the 221 V8 at intro. This architecture never changed from inception until today.

1964.5 Ford Mustang & Engine

While the Fairlane received the Hi-Po 289 in early 1964, the Mustang soon followed – being announced prior to the 1965 model run. The generator marks it as a 1964 issue.

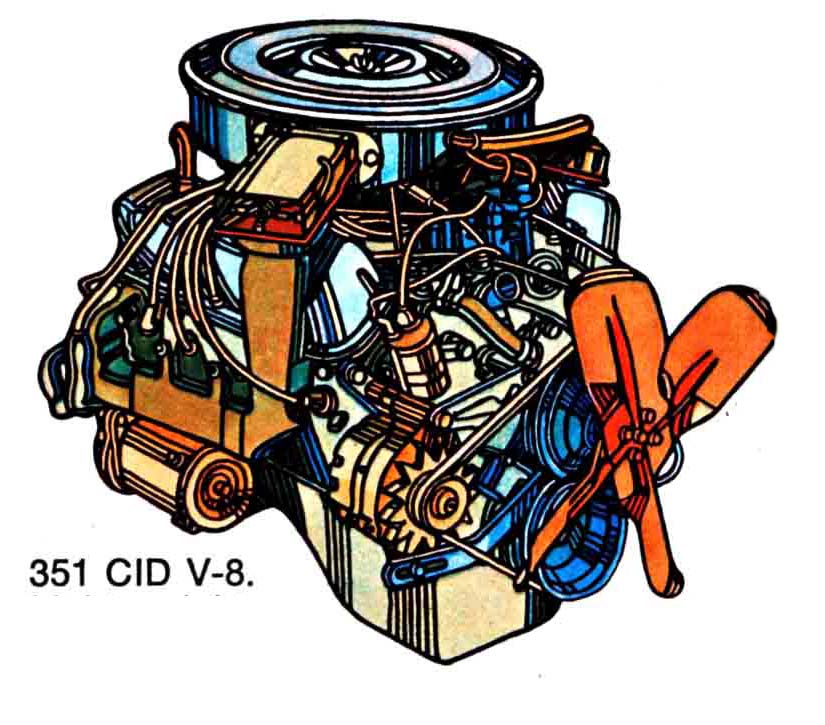

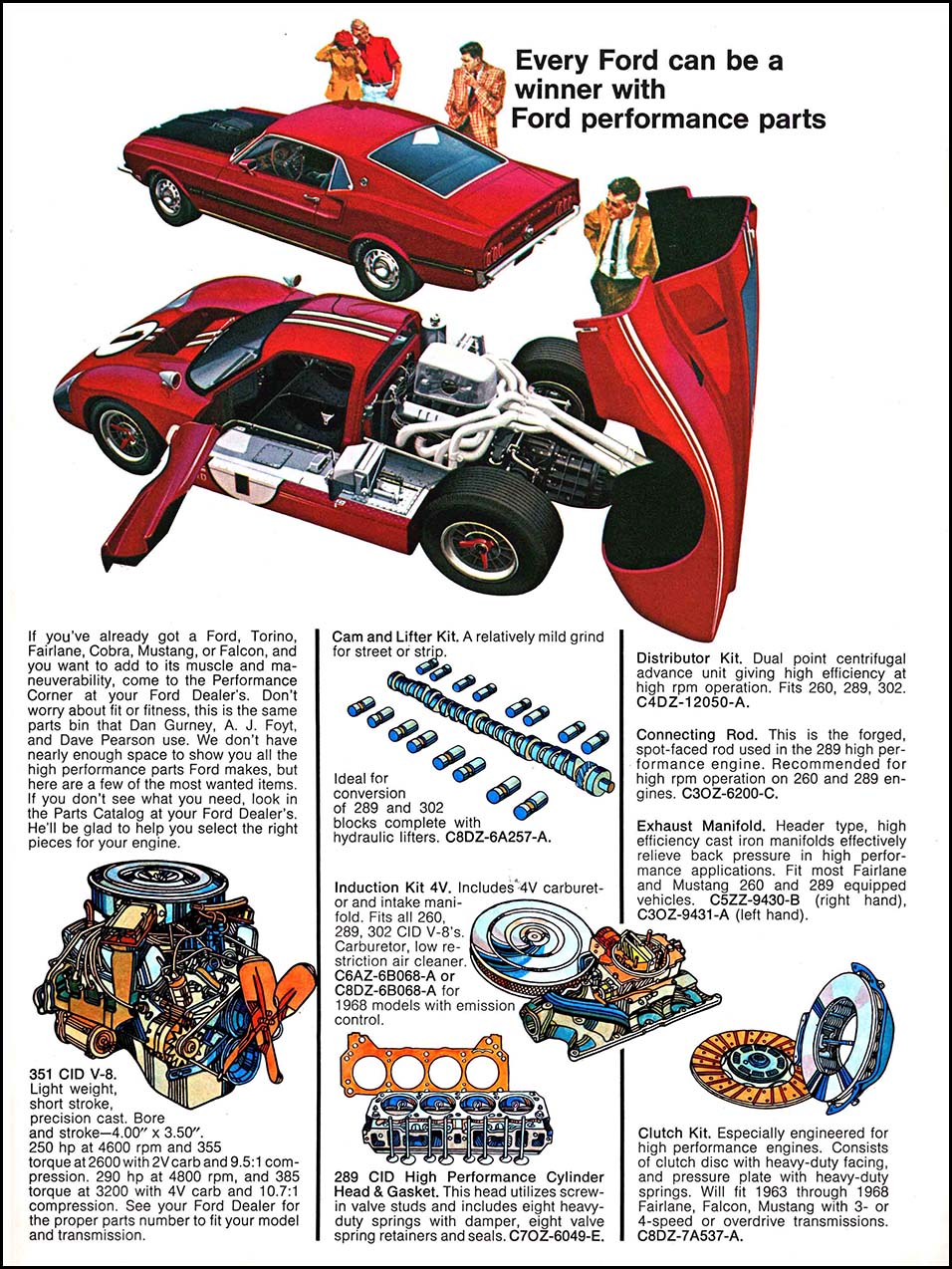

Fords Amazing Small block2

his page in the Ford Performance Buyer’s Digest pamphlet lists with glowing terms the new 351W High Performance Engine.

In 1965 the compression ratio of the base 289 was raised to 9.3:1, increasing power and torque to 200 hp @ 4,400 rpm and 282 ft lbs @ 2,400 rpm. The four-barrel version had its compression increased to 10.0:1, and was now rated at 225 hp @ 4,800 rpm and torque went up to 305 ft lbs @ 3,200 rpm.

289 engine specifications were unchanged for 1966 and 1967. In 1968, the four-barrel 225 hp engine was dropped, leaving only the two-barrel which was reduced back to 195 hp. 1968 was the last year of production for the 289 in the U.S. The 289 was also used in the first Australian Ford Falcon GT, the XR Falcon GT.

The 289 “Hi-Po” or “K-Code”

A high-performance version of the 289 engine was introduced late in the 1963 model year as a special order for Ford Fairlanes. The engine is informally known as the “Hi-Po” or “K-code” after the engine letter used in the VIN of cars so equipped. Oddly, this engine was introduced in 1963 as the only 289 engine available in the intermediate Fairlanes. Lesser powered cars had the 260 engine in that year. Starting in June 1964, it became an option for the Mustang. However, K-code Mercury Comets were the 210 HP 4 bbl carb engine, not the High Performance engine as the K-code Fords.

The Hi-Po had solid lifters with hotter cam timing; 10.5:1 compression; a dual point, centrifugal advance distributor; smaller combustion chamber heads with cast spring cups and screw-in rocker studs, low restriction exhaust manifolds and a larger, manual choke 595 CFM carburetor. The water pump, fuel pump, and alternator/generator pulley were altered, and the Hi-Po’s fan was unique to that engine, due to its higher rpm capabilities. Other improvements included thicker main bearing caps and balancer, larger diameter rod bolts, and a hardness-tested and counterweighted crankshaft. The Hi-Po was rated at 271 hp @ 6,000 rpm and 312 ft lbs of torque 3,400 rpm.

The Hi-Po engine was used in modified form by Carroll Shelby for the 1965-1967 Cobra and Shelby GT350, raising rated power to 306 hp @ 6,000 rpm. It used special exhaust headers, an aluminum hi-rise intake manifold, and a larger Holley carburetor. The Shelby engine also had a larger oil pan with baffles to reduce oil starvation in hard cornering. Shelby also replaced the internal front press-in oil gallery plugs with a screw-in type plug to reduce chances of failure. From 1966 to 1968, Shelby offered an optional Paxton supercharger for the 289 on Shelby GT350s, raising its power to 390 hp.

The K-code Hi-Po engine’s popularity was reduced once the 390 and 428 big-block engines became available in the Mustang and Fairlane lines. They offered similar power and far more torque for far less cost.

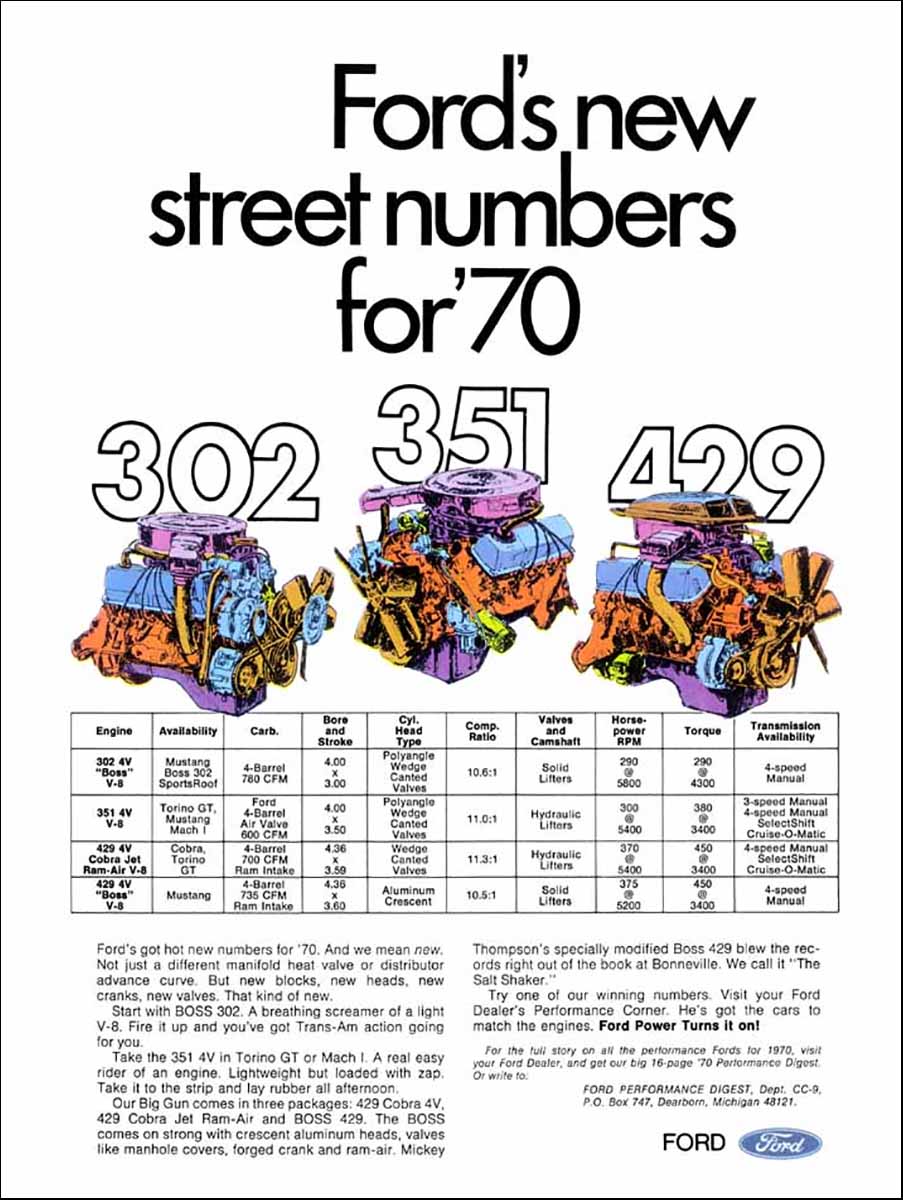

The 302

For 1968, the small block Ford was stroked to 3.0″, giving a total displacement of 302 cu in. The connecting rods were shortened to allow the use of the same pistons as the 289. It replaced the 289 early in the 1968 model year. The most common form of this engine used a two-barrel carburetor, initially with 9.5:1 compression. It had hydraulic lifters and valves of 1.773″ (intake) and 1.442″ (exhaust), and was rated at 210 hp @ 4,600 rpm and 290 ft lbs of torque at 2,600 rpm.

An optional four-barrel version was rated at 230 hp @ 4,800 rpm and 310 ft lbs of torque @ 2800 rpm (single exhaust) and 235 hp @ 4,800 rpm and 318 ft lbs of torque @ 3200 (dual exhaust).

For 1968 only, a special high-performance version of the 302 was offered for the Shelby GT350. Its main features included a high-rise aluminum intake manifold, a larger Holley four-barrel carburetor, and bigger valves; 1.875″ (intake) and 1.6″ (exhaust). It had a longer-duration camshaft, still with hydraulic lifters. The block was a higher nickel content casting made in Mexico. “Hecho en Mexico” casting marks are present in the lifter valley, and its main strength was the appearance of much larger and stronger two-bolt main bearing caps on the engine’s bottom end.

The heads had special close tolerance pushrod holes to guide the pushrods without rail rocker arms or stamped steel guide plates. The combustion chambers also featured a smaller quench design for a higher compression ratio and enhanced flow characteristics. Heavy-duty connecting rods with high strength bolts and a nodular iron crankshaft were also included in this package. It used high flow, cast iron exhaust manifolds similar to those on the 289 Hi-Po K-code engine. It was rated at 315 hp @ 6,000 rpm and 333 ft lbs of torque @ 3,800 rpm. This engine block is considered the strongest production 302 block other than the Boss 302 and the Trans Am 302. The package cost $692. It was not popular and did not return for 1969. The heavy duty Mexican 302 block was produced throughout the late 1970s and early 1980s and was utilized in Ford trucks and vans.

In 1968 Ford also offered a “Tunnel Port” HD 302 for Trans Am racing. Configured much like the Hi-Po 289, it received special hi-flow heads. Unfortunately the engine only made hp in the upper rpm ranges and was found to be unsuitable for road racing and was withdrawn in favor of the Boss 302 for 1969.

The last year for the 302 4-barrel was 1970. In 1971 the 4-barrel was now a 351 cu. in version of the small block. Thereafter, emission regulations saw a progressive reduction in compression ratio for the 302 two-barrel, to 9.0:1 in 1972, reducing SAE gross horsepower to 210 hp. In that year U.S. automakers began quoting horsepower in SAE net ratings; thus the 302 two-barrel was rated at 140 hp. By 1975 its power dropped to 122 hp. Not until fuel injection began to appear in the 1980s would net power ratings rise.

351 Windsor Heads

| Model | Carb | Combustion Chamber | Intake Valve | Exhaust Valve |

| 1969 Hi-Perf | 4V | 58 cc | 1.84" | 1.54" |

| 1969-76 | 2V | 60 cc | 1.84" | 1.54" |

| 1977-80 (302 head) | 2V | 69 cc | 1.78" | 1.45" |

The 351 Windsor (351W)

In response to Chevrolet’s 350 and Chrysler’s 340 cubic inch V8s, Ford developed a larger displacement small block, based on the recently released 302 cu. in V8, available beginning in 1969. The 351 cu in (5.8 L) Windsor featured a 1.3″ taller deck height than the 302, allowing for a longer stroke of 3.5″.

Although related in general configuration to the 289-302 and sharing the same bell housing, motor mounts and other small parts, the 351W was a unique, tall deck block, with larger main bearing caps, and thicker, longer connecting rods. These changes added approximately 25 lbs. to the engine’s dry weight. The 351’s distributor is also different as it is designed to accommodate a larger oil pump shaft that feeds a larger oil pump. It had its own distinct firing order: 1-3-7-2-6-5-4-8 versus the 221-302s 1-5-4-2-6-3-7-8.

The 351W also had a different cylinder head than with a larger combustion chamber than the 289-302. The early 1969 and 1970 heads had larger valves and ports for better performance. The head castings and valve head sizes varied from 1969 to 1976. One of the differences was that the 1969-1974 used an 18 mm plug, the 1975 and up used a 14 mm plug. From 1977 onward, the 351W shared the same head casting as the 302, differing only in bolt hole diameters with 7/16″ for the 302 and 1/2″ for the 351W.

Early blocks (casting C9OE-6015-B) had enough metal on bearing saddles 2, 3, and 4 for four bolt mains, and as with all Ford small blocks, were superior in strength to most later lightweight castings. The 1969 to 1974 blocks are considered superior in strength to the later blocks, making these early units the most desirable in the SBF engine family. After 1970, the 351W 4-barrel was replaced by the 351 “Cleveland”. However, upon the demise of the Cleveland after 1982, a four barrel version (casting E6TE-9425-B) was re-introduced for use in light trucks and vans. In 1988 fuel-injection replaced the four barrel carburetor. Roller lifters were introduced on the 351W in 1994.

The block underwent some changes during its life. In 1971, the deck height was extended from 9.480″ to 9.503″ (casting D1AE-6015-DA). This was done to lower the compression ratio without the need to change the piston or cylinder head. In 1974 a boss was added on the front of the right cylinder bank to mount the air injection pump (casting D4AE-A). In 1974 the oil dipstick tube moved from the timing case to the skirt under the left cylinder bank near the rear of the casting. In the 1990s, the rear main seal was changed from a two-piece component to a one-piece design. In the 1980s, roller lifters were added.

The original connecting rod beam (forging ID C9OE-A) featured drilled oil-squirt bosses to lubricate the piston pin and cylinder bore, and used rectangular head rod bolts mounted on broached shoulders. There were a number of fatigue failures attributed to the machining of the rod, so the bolt head area was spot-faced to retain metal in the critical area, requiring the use of what are known as “football head” bolts.

In 1975, the rod forging (D6OE-AA) was updated with more metal in the bolt head area. At this point, the oil squirt bosses were drilled for use in export engines only, where the quality of accessible lubricants was questionable. However, the rod cap forging remained for all (part id C9OE-A). In 1982, the “Essex” V6 engine used a new version of the 351W connecting rod (E2AE-A), the difference between the two parts was that the V6 was machined in metric and the V8 in inches. The cap featured a longer boss for balancing than the original design.

When the 351 was introduced in 1969, it was initially rated at 250 hp with a two-barrel carburetor or 290/300 hp with a four-barrel. When Ford lowered the compression and switched to SAE net power ratings (1972) it was rated at 153 hp (2-bbl) and 161 hp (4-barrel).