Turbo Tranny Tech Facts

TH 400, 425, 375, 350, 200, 7004R, 4L60E – what do all these mean to the muscle car enthusiast and where is the advantage? This series of articles will try to clear the air and let you at least understand where each transmission fits in the scheme of things and the advantages and disadvantages of each.

The first in this series of articles will be a general explanation of each transmission and where it fits in the GM family. Further articles will explore modification and swap capabilities, including the advantages of adding an overdrive 4-speed unit in place of your GM muscle car’s 3-speed. Two-speed automatics will be discussed in a separate series.

We’ re going to take it from the top with the first, introduced but let’ s first throw a little history at you right now so you can see the how and whys of the Turbo Hydra-matic family.

The Beginning

Before the TH family was born, GM had a storied history with automatic transmissions, starting with the original Hydramatic, which was produced from 1939 (in Oldsmobile first!) and was produced in its original form through 1955. In 1956 it was improved and called the “Jetaway” Hydramatic. It was substantially smoother than the original Hydramatic, but also more complex and expensive to produce, as well as less efficient.

This prompted the “Roto-Hydramatic” or “Slim Jim” introduced in 1961 for Pontiac level cars and Oldsmobile. The Slim Jim was prone to failure and could not handle the abuse of the original Hydramatic or Jetaway. Because of this, Caddy and Pontiac Bonneville continued to use the Jetaway Hydramatic. GM knew that the Roto-Hydramatic and the complex Jetaway needed to be replaced and came out the TH-400 in 1964. The design concepts of the TH-400 were incorporated into all GM automatic transmissions going forward – to this day.

Nomenclature

Surprisingly, the numbers associated with the transmissions are not just neat names assigned by marketing, though the stuff in front of the numbers was usually the result of GM’s ad men. Thus, the higher the number in the nomenclature in the earlier transmissions, the higher the torque rating. “400” meant that the transmission could handle 400+ ft. lbs of torque. “350” meant 350 ft. lbs, and “375”, well you get it.

In 1987 GM changed the naming structure, for example, the TH 400 was renamed to the “3L80” which now meant three forward speeds, longitudinal positioning (fore and aft), and an arbitrary strength rating of 80. Thus, the later 4L80 means 4 speed, longitudinal, and 80 strength rating.

In the following, the transmissions are listed in their order of introduction by GM

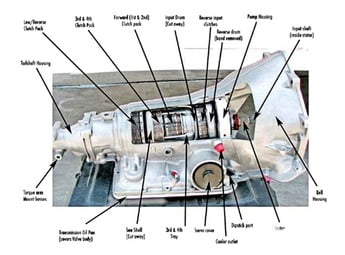

Turbo Hydra-matic 400

The TH-400 or Turbo 400 was a three-speed automatic transmission first introduced at the beginning of the 1964 model year in Cadillacs and Buicks (under the name Super Turbine 400). In the following year, Oldsmobile and Pontiac and some full-sized Chevrolets received it.

The TH 400s produced in 1964-67 were equipped with a torque converter that incorporated the Switch-Pitch variable-pitch stator, which allowed variable torque application at start off and cruise. These can be identified outside the vehicle by the kick down switch on the tranny which has two prongs instead of one. His concept actually came from the Buick “Twin Turbine” Dynaflow transmission used from 1955 through 1963.

The TH 375, is simply a TH 400 with a long output shaft that mates to the smaller TH 350 drive shaft yoke. This can be identified by “375-THM” cast into the tail housing. Internally the clutch packs originally had fewer friction plates. The 375 rating was a result of the smaller yoke and fewer clutch friction plates.

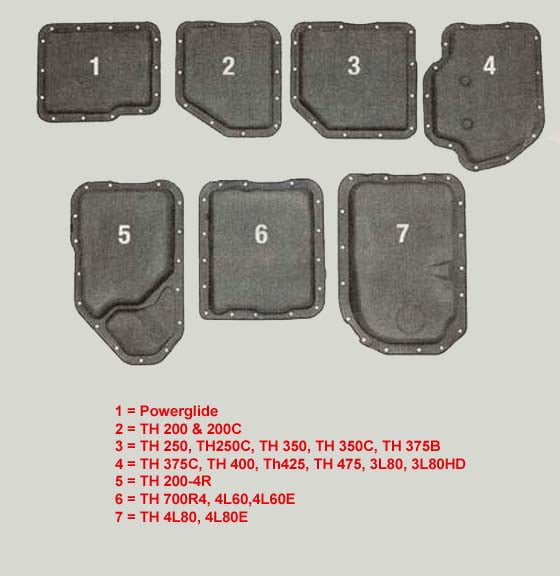

To confuse the matter, some heavy duty TH 350s were also designated THM375-B. The key to telling the difference is the shape of the pan. Later, there was a 3L80HD, which is sometimes referred to as a “Turbo 475”. This 3L80HD has a straight-cut planetary gear set and there is no externally visible way to determine whether the transmission contains the straight-cut planetary gear set. Some 3L80HD units had an extra deep oil pan, but it is not a reliable indicator. The TH 425 front wheel drive transmission of the Toronado and Eldorado shares almost all its internal parts with the TH 400.

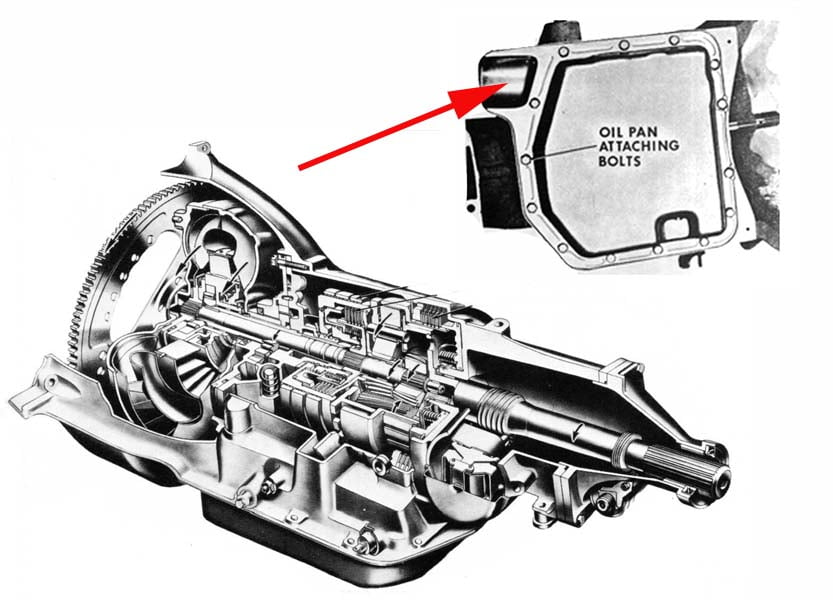

Your best bet for identification is the transmission oil pan. See the pictures at right.

By 1980, usage of the TH 400 in GM passenger cars started to decline. The demand for better gas mileage convinced GM to design a 4-speed auto, with 4th gear being overdrive. By 1984 GM passenger cars no longer used the TH 400. From 1984 through 1986 the C- and K-series full size Chevrolet/GMC pickups and G-series vans. Thereafter it was renamed to the 3L80 and used more in heavy duty applications. The United States Army HMMWV is the only vehicle using the 3L80. The civilian Hummer H1 originally used the 3L80, but since the mid 1990s the 4L80E was used.

Through the end of the ’70s substantially more CBOP (Cadillac/Buick/Oldsmobile/Pontiac) bell housing TH 400s were produced than any other version. From 1964 until 1967, the Buick version used a different bell housing to mate to the old style “Nailhead” engine. Chevrolet used a separate bell housing and are harder to find. The TH 400 was never produced with a multi-case bell housing.

Other auto manufacturers have used the TH 400 and its 4L80E successor, including Ferrari, Jaguar, Rolls-Royce and Bentley, AM General; and Jeep. Early Jeep TH 400s used an adapter between the engine and transmission bell housing while later models had an AMC specific bell housing. Though identical except for the bell housing pattern, the Jeep version used until 1979 was mated to the Dana model 18,20 and was the only transmission used with the Borg-Warner 1305/1339 all-wheel-drive transfer case.

TH 400 transmissions are very popular due to their great strength, which comes from the use of a cast iron center support to suspend the transmission’s concentric shafts that join the clutch assemblies to the gear train. The center support, which is splined to the interior of the transmission’s case, also provides a robust reaction point for first gear. Since the first gear reactive force is evenly distributed around the periphery of the case, the types of mechanical failures that have plagued other transmissions under hard use are rare.

The TH 400 was the first three-speed, Simpson-geared automatic to use overrunning clutches for both first and second gear reaction, a feature that eliminated the need to coordinate the simultaneous release of a band and application of a clutch to make the 2-3 gear change. Because of this and the use of a large, multi-plate clutch to provide second gear reaction, the TH 400 is able to withstand very high input torque and an enormous number of shifting cycles, as would be encountered in frequent stop-and-go driving.

As we said earlier, 1987 was the year that GM changed the nomenclature of the Turbo Hydramatic transmissions, with the TH 400 renamed to “3L80”. At this time, a 3L80HD was introduced for use in passenger trucks. Significant is that almost all of the TH 400, 3L80, and 3L80HD’s components are interchangeable.

GM Turbo Hydra-Matic 400/3L80 Gear Ratios: 1st: 2.48.1; 2nd: 1.48.1; 3rd: 1.00.1; Reverse: 2.08.1

Turbo Hydra-matic 350

The Turbo Hydra-matic 350 was first used in 1969 GM cars. It was developed jointly by Buick and Chevrolet to replace the two-speed Super Turbine 300 and aluminum case Powerglide transmissions. The 350 and its 250, 250C, 350C and 375B derivatives have been manufactured by Buick in its Flint, Michigan, plant and by Chevrolet in Toledo and Parma, Ohio, and Windsor, Ontario. The TH 350 was to some degree based on the earlier Buick Super Turbine 300 and some components interchange between the two.

One important difference in the TH 350 compared to the TH 400 is there is no fixed center support midway through the gear train, this important difference in layout permitted TH 350 to be adapted to the Corvair where the drive and driven ends are the same. This feature was not exploited but Corvair may have eventually used the TH 350 had it remained in production, and Chevrolet was experimenting with mid-engine Corvette designs that might also have used this advantage had they ultimately reached production. Air cooled versions, with a baffle on the torque converter and air intakes cast into the bell housing appeared mid 1972 in Chevrolet Vega and Nova 6.

One should remember that the TH 350 was designed for lower torque applications, and as such has some weak points when compared to the TH 400. The first weak point is excessive end-play between the pump and center support and use of a relatively narrow bushing in the drum, both of which can result in wobble of the direct clutch drum. This weak point can be addressed by using an extra thrust washer between the planetary gear and direct clutch by and using a wider aftermarket bushing in the direct clutch drum. Another weak point is the relatively thin center support and the lightweight matching splines in the case. This weakness can be addressed by using an inexpensive aftermarket case saver kit. Fixing these two issues will result in a TH 350 that is nearly as durable and reliable as a TH 400.

In 1980 a lock-up torque converter was introduced and the transmission was then called TH 350C. This transmission was phased out in 1984 in GM passenger cars and replaced by the 700R4. Chevrolet/GMC trucks and vans used the TH 350C until 1986. The lock-up torque converter was unpopular and at one time B&M Racing marketed a conversion kit for TH 350-Cs to remove this feature. The standard TH350 is still very popular in drag racing, street rodding and restomods.

Gear Ratios for the TH 350: 1st: 2.52.1; 2nd: 1.52.1; 3rd: 1.00.1; Reverse: 1.94.1

Turbo Hydra-matic 250

The THM250 is a derivative of the TH 350 and was introduced in 1974 in Chevrolets as a Powerglide replacement. Internally, the THM250 is a TH 350 without the intermediate clutch pack. Instead, it has a band adjuster similar to the Powerglide. After being phased out for the TH 200/200C. It was reintroduced in 1979 as the THM250C in the wake of the failure-prone THM200/200C.

Gear Ratio for the TH 250 and 250CC: 1st: 2.52.1; 2nd: 1.52.1; 3rd: 1.00.1; Reverse: 2.07.1

The Turbo Hydra-matic 200

In 1976 GM developed a lighter-duty version of the TH 350 with lightened materials – primarily aluminum alloys – in place of ferrous materials in the clutch drums and oil pump for introduction . The result was the Turbo Hydra-matic 200. The GM vehicles which first saw use of the THM200 were the GM X-Bodies; Chevy Nova Buick Apollo, Pontiac Ventura, and Oldsmobile Omega.

Unfortunately, this transmission was notorious for failure when used behind the V8 engines of the day, where the main shaft, among other things, would fail. Starting with the 1979 model year, vehicles which had the THM200/200C as standard equipment were optioned with the THM250-C.

In the same time period it received a lockup torque converter. Some internal components (primarily the low/reverse clutch drum and planetary gears) were later shared with the Turbo Hydra-matic 200-4R. THM200/200Cs were produced until 1987.

The Gear Ratios for the 200C: First 2.74:1.0; Second 1.57:1.0; Third 1.00:1.0; Reverse 2.07:1.0

Turbo Hydra-matic 200-4R

In the 1981 model year the 200-4R (sometimes called 200R4) was introduced. Internally, the components which were prone to failure in the THM200 were improved, and this transmission was used with higher-power applications – primarily the Buick Grand National and the 1982 Chevy Corvette. Vehicles powered with the Oldsmobile 5.7 L Diesel powerplant were coupled with the 200-4R in place of the 200. The 200-4R was configured with several different torque converters and gear ratios depending on the vehicle application.

The 200-4R has a multi-case bellhousing for use with both Chevrolet on one hand, and Buick/Olds/Pontiac (BOP), and Cadillac powerplants on the other. Since the external dimensions are similar to the THM-350, 200-4Rs are often swapped in place of THM-350s in older vehicles to provide an overdrive gear. Early models used a PRND321 on the instrument cluster, while later models had PRN(D)D21, with the left D identified as the overdrive gear by a square or oval ring.

The THM200-4R was phased out after 1990 – its final usage was in the GM B-body lineup coupled to either a Chevrolet 305 or an Oldsmobile 307 engine. A HD version of the 200-4R was used in some 80s Caprice 9C1 police package using the internals from the earlier Buick Grand National.

Turbo Hydra-matic 700R4 and later 4L60, 4L60E and 4L65E

The 700R4 was introduced in 1982 for use in Chevrolet and GMC mid-sized vehicles. In 1990, the 700R4 was renamed the 4L60. The transmission was used for 10 years, meaning there are a lot of vehicles in scrap yards with this unit. The aftermarket has turned to the 700R4 as a heavy duty replacement for the 200-4R for use in muscle cars. 1992 was the last year of widespread usage of the 700R4/4L60. However, the 1993 Camaro, Corvette and GMC Typhoon were equipped with the last production 700R4’s.

In 1992 electronic controls were added, and it became the 4L60-E. The 4L60E went into service in trucks, vans, and SUVs in 1993, with some vehicles receiving the 4L60 (no electronic transmission control). It was also installed in all RWD passenger cars (the Corvette, Pontiac F bodies and any rear drive B/D bodies, starting in 1994.

In 2001, an updated version the 4L65-E, was introduced. This version added five-pinion planetary gears along with an improved high-strength output shaft. These changes were installed to withstand the 300+ ft. lbs of torque the Chevrolet 6.0 liter Vortec engine.

700R4 Technical Info

Many trans swappers like the 700R4, because of the replacable bolt-on bellhousing. Therefore, we have included some key info. The 700R4 can be identified by the oil pan having a rectangular shape being longer front-to-rear than side-to-side and held to the transmission by 16 bolts: three bolts front and rear; five bolts left and right sides.

The original version of the transmission had a 27-spline input shaft which was a common failure point. In 1984, 700R4’s designed for use behind Chevrolet small block V8’s received a 30-spline input shaft similar to those found on classic TH 400 transmissions These units also used a different torque converter than its 2.8 V6 and 2.2 L4 powerplants.

Between 1984-1987, internal components, from the ring gear to the oil pump housing, were updated. In 1995, the 4L60E received a computer controlled (PWM) lockup converter. Some 1994 full size Chevy trucks have been seen with PWM. Model year 1995 (late 1994) are all equipped with PWM. For those so equipped “PWM” will be stamped into the front of the transmission below the input shaft.

In 1999, GM introduced a redesigned 4L60E transmission case that incorporated a bolt-on bellhousing and an 6 bolt tail-housing. These are referred to as “Late-Model 4L60Es”, Both transmissions are generally the same internally with the bolt-on case being the only major difference. Generally, the Early-model and Late-model 4L60Es are not interchangeable. To see an article on the modified 700R4 in a GM A-Body muscle car, click here.

The gearing for the 700R: First 3.06:1.0; Second 1.63:1.0; Third 1.000:1.0; Fourth 0.70:1.0; Reverse 2.29:1.0

The Turbo Hydra-matic 4L80

In 1991, the four-speed overdrive version, the 4L80-E, replaced the TH 400 in Chevrolet/GMC pickups, vans, SUVs, and commercial vehicles. The 4L80E (and its successor 4L85E) was the first Hydramatic to incorporate electronic controls.

The 4L80-E (and similar 4L85-E) includes 4 forward gears and is an evolution of the Turbo Hydra-matic 400. 4L80-Es have been optioned only in Chevrolet/GMC pickups, vans, and commercial vehicles, and the Hummer H1. Because of this, there are a significant number of these transmissions in scrap yards. The 4L80/85 can be converted so as to not use electronic controls, making is an excellent replacement for high torque muscle cars.

The 4L80-E (and similar 4L85-E) is a series of automatic transmissions from General Motors. Designed for longitudinal engine configurations, the series includes 4 forward gears. It is an evolution of the Turbo Hydra-matic 400. The case however is larger and the oil pan is entirely different, so don’t think you can swap the guts into your TH 400. The other aspect is that the bellhowsing is integral with the case and is set up for a Chevy block.

There are companies who can ut off the front of the case and attach a BOP bell housing, but this is not a cheap fix. If you are thinking of a HD OD unit for your Olds, consider a 700R4. To see an article on the modified 700R4 in a GM A-Body muscle car, click here.

GM Turbo Hydra-Matic 4L80E Gear Ratios: First 2.48:1.0; Second 1.48:1.0; Third 1.000:1.0; Fourth 0.75:1.0; Reverse 2.09:1.0

Two Other Trannys

Many A Body Intermediates were equipped with both the Chevrolet Powerglide and the Buick sourced Super Turbine 300 transmission. While no Oldsmobiles received the Powerglide, it could be found in the Chevrolet A-body.

The ST-300 (Super Turbine in Buick – Jetaway in Olds) was used by BOP in A-bodies from 1964 through 1969, including from 1965-1966 in the auto trans versions of the 442, GTO and Gran Sport. This was a rather unique transmission and used some of the features of the Dynaflow and the later TH-350, though it was only 2-speed.

It ran the two position stator of the 65-67 TH 400, giving it what seemed to be three speeds. Other than the torque converter, the two position stator switch and the kickdown switch, which could be used on a switch-pitch 400, it shared little with any TH series transmission.

Next: Considering an overdrive TH? Which one is best for you?

Gm-Turbo-Tranny-2

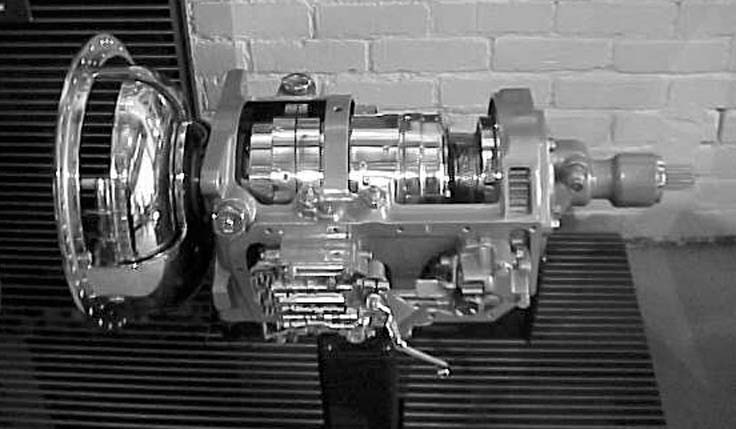

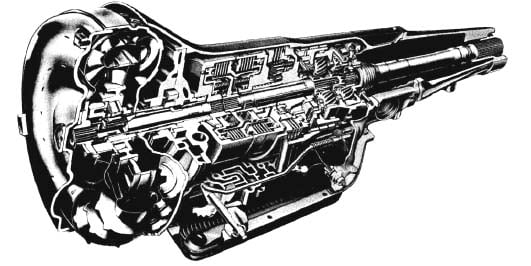

The original Hydramatic was smooth, sturdy and easy to service. It was a true 4-speed automatic.

Gm-Turbo-Tranny-3

The Roto-Hydramatic or “Slim Jim” was not sturdy enough to handle the torque of the 400 cubic inch engines of the 1961-1964 period.

Gm-Turbo-Tranny-4

The best way to identify the different modern Hydramatic transmissions is by their oil pans.

Gm-Turbo-Tranny-6

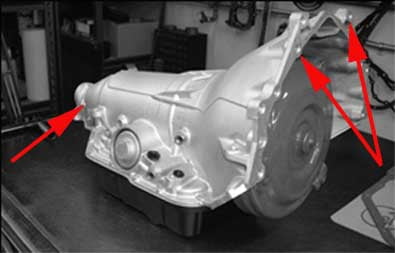

The Chevy only TH 400 uses different attachment points on it bell-housing, making the case unusable for BOPC swaps

Gm-Turbo-Tranny-7

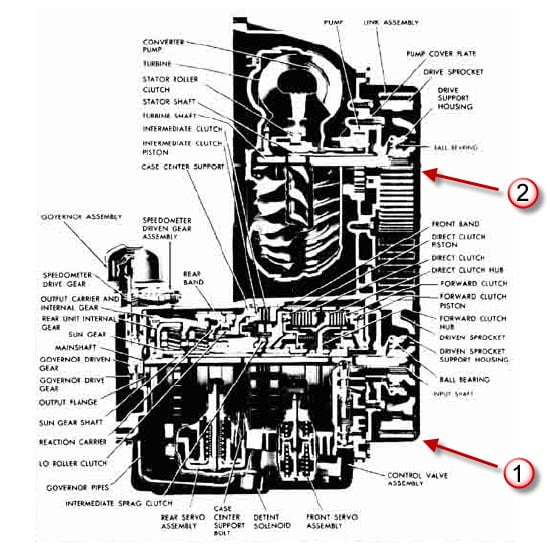

The TH 425 Transmission was used in the 1966-1977 Toronado and Eldorado. It is a true logitudinal trans, with the trans flipped around (1) to face backwards and coupled to the torque converter via a chain drive (2)

Gm-Turbo-Tranny-8

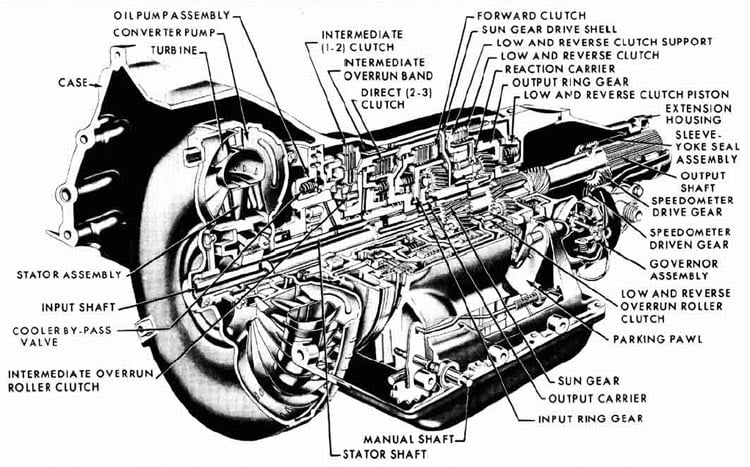

The TH 350 was introduced in 1969 as a lower cost 3-speed auto alternative to the TH 400.

Gm-Turbo-Tranny-10

The lockup version of the TH 350 (TH 350C) can be identified by the “C” on the pump housing and the Chevy/BOP combined bell housing bolt pattern.

Gm-Turbo-Tranny-11

The TH 200 looks similar to the TH 350, but the guts are weaker. Note that the 200’s tail shaft housing is integral with the case, unlike the TH 400 and 350.

Gm-Turbo-Tranny-13

The TH 200-4R looks very similar to the TH 200 and is as long as the TH 350. It has a totally different oil pan, however. See the pan ID above. Note the universal bell housing mounts

Gm-Turbo-Tranny-14

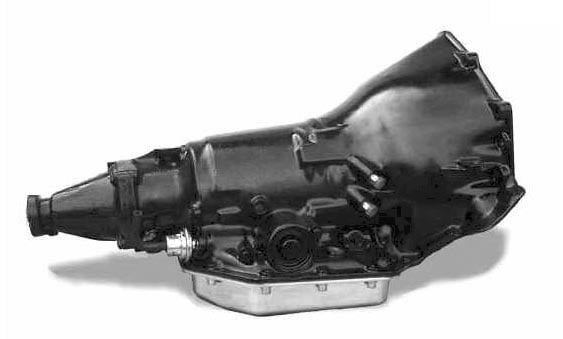

he TH 700R4/4L60 Looks much more like the TH 350, including the removable tail shaft housing. Later versions had a removable bell housing. The 700 has its own distinct oil pan. See the pan ID above

Gm-Turbo-Tranny-15

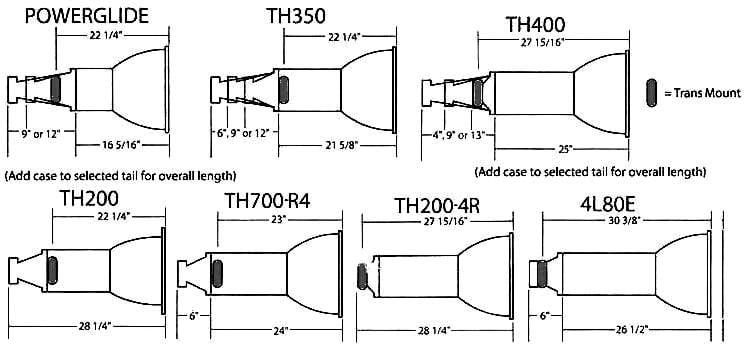

This diagram shows the size, distance, trans mounting position for the various TH trannys