Made In Pontiac, Part 3

by Eric White, Reprint with Society permission only

Wild About Cars: Your GTO came in to the dealership three days later?

Carl Papke: The red car came in three days after I bought the one I settled for. I wasn’t pleased. A guy from Kingston, named Arnold Growe, bought the car. We drag raced on M-46 west of Kingston that night, and he blew my shorts off! It had a 3.90 rear end in it. It had tri-power. It had the close ratio four-speed, and it was a hauler. It didn’t last long. He blew that motor up within seven days of the day he took delivery on the car. He blew it up a half a mile south of M-46 on M-53. He got out and was hitchhiking into town about five miles away.

By the time he went to the dealer and came back with the wrecker, two guys was stealing the tri-power off of that car. They had it all but two bolts, and when the wrecker pulled up they jumped in their pick-up and split. They didn’t get it [the tri-power], but they almost had it.

WAC: This is in rural America, 1965.

CP: Right here in Marlette, Michigan, and it was happening then. If you wanted to lose your four-speed transmission, park it in a lot and go to work. It was almost guaranteed that it was gone. I never had anything stolen off any of my cars around here. I never had any problems. Maybe that was because people knew me. You know, let’s not take this, this is Carl’s. Everybody knew me. But then I didn’t take anything off anybody else’s, and it didn’t matter if I knew them or not.

There was people going around stealing parts. If you were drag racing and tearing transmissions up, you can’t afford to drag race for long in 1965 under the Pontiac Motor pay code. Maybe you had a wife and a kid at home. You couldn’t afford that. So, when you seen them drag racers, they were getting free parts. That was standard procedure to follow. You couldn’t be out buying transmissions every other week.

WAC: Of course the factory wouldn’t keep replacing those broken parts under warranty indefinitely.

CP: The factory was real good. From the date I took delivery of that ’65, six weeks later it was back at the dealership. It was sitting in there with the rear end out of it. It was sitting in there with the transmission out of it, and the engine was out of it. The motor had sand holes in the block. That was a factory defect. It would use oil. If you went up and drag raced it twice, it was a quart low on oil. Most of that oil was laying right on top of the tri-power air cleaners. It would just circulate.

Within a week of getting that car, the insulation pad under that hood had soaked up so much oil that it had fallen into the fan, and I had pawed it out of there and threw it away. It was destroyed. I knew there was a problem with the car, but it took the dealer six weeks to realize there was a problem with it. He kept tellin’ me it’ll break in, it’ll do this and it’ll do that. It never did anything but get worse.

When they took it into the dealership, I had the synchronizers out of second gear. The pinion in the rear end. I was drag racing a kid by the name of Ron Chappel, and part of the pinion, I forget the correct name for it, but it drove it right out through the rear end cover. It looked like someone took a twelve-gauge slug and put a hole through there. It had busted, and that one half was freewheeling. It caught just right, and the gears, as they came around, just pushed it through there.

The car still would go down the road under its own power, but it was clatterin’ and clangin’ with grease leaking out of it. I did drive it three miles into Marlette. They repaired the rear end. The dealer said, I don’t know how you did that. I’ve never seen one do that before. I said I didn’t have any idea how that happened either. They knew it was getting drag raced. But they stood behind it. They put synchronizers in the transmission, and they put a new engine block in it. I kept the car for another year, and never had any more problems with it. But basically I was driving a lot easier because I knew they weren’t going to do anything else to that car. I was buying new parts myself after that.

WAC: How many fellow workers bought cars that were built in that plant?

CP: Well, there were two kinds of people in the plant. There were people who said, I wouldn’t own this junk. And there were people that wouldn’t buy anything else but that stuff. It didn’t seem like there was anybody in between. They either loved them and bought ’em, or they drove Chevrolets or Fords. I would say 75% of the people in that plant loved Pontiac cars, and probably drove ’em.

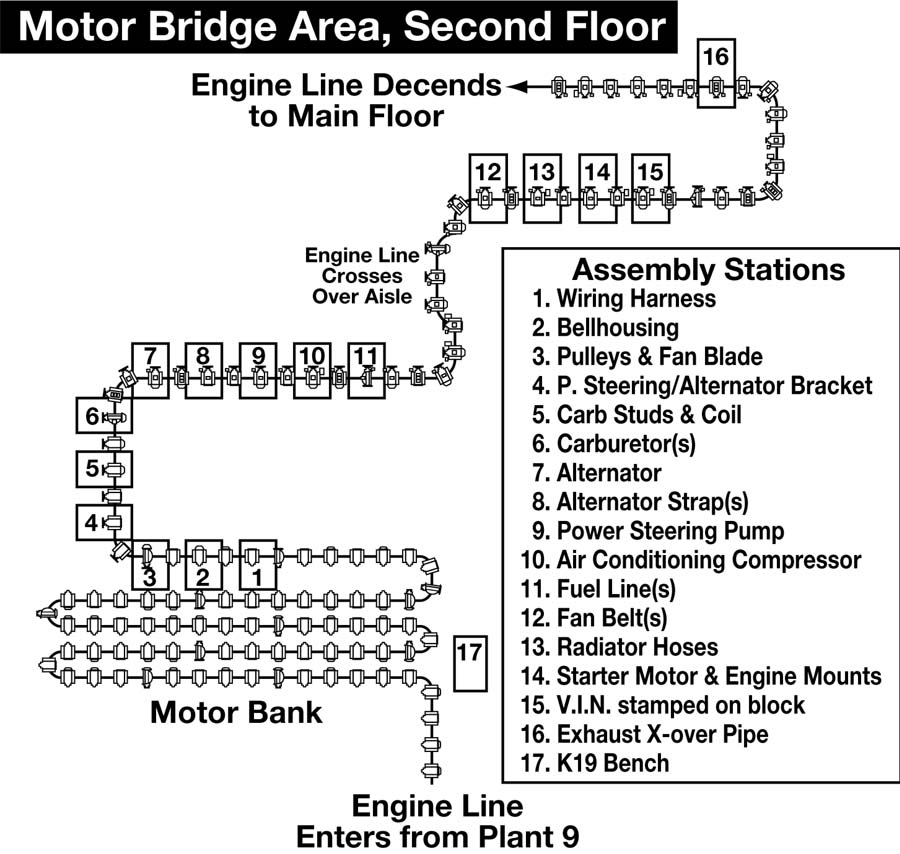

WAC: What other jobs did you do on the motor bridge?

CP: While I was utility man on the motor bridge I did basically everything to a motor externally. I hung starters, installed alternators and alternator brackets, carburetors, power steering pumps, power steering brackets. The bracket that would go onto the driver’s side head was an aluminum bracket.

If the car didn’t have power steering, it had an aluminum bracket that was a different design, and it held just the alternator. I installed the straps that hold the belts tight. I put belts on. One guy’s job was checking each belt to make sure it was under the right tension. I did that.

WAC: It’s been said that all fan belts went on the engine so that the numbers on the belt could be read from the front of the engine. Is that true?

CP: I don’t remember them saying how to put a belt on. I just took a belt and stuck it on. If the part number came out backwards, that was fine. If it was on frontwards, that was fine too. There was a woman about fifty years old named Helen who put the belts on. I know she never looked at part numbers to see if the belts went on right or not.

They came shipped in the box, and she was in the habit of going and grabbing one, turning, and putting it on the motor. If it went on right that way, maybe nine out of ten of them went on like that. But as a set pattern, no. They would be stacked one way in a box when they came from the shipper. If they came out of the box that same way, chances are it would have gone on the motor that same way. If it went on so that you could read them, it would have been purely accidental. They didn’t look at them. They didn’t care what that part number was on that belt.

That number didn’t mean anything to her, as long as it came out of the right bin. They all came in on skids in four-foot high wooden crates. There would be maybe two thousand belts in that box. They weren’t individually wrapped. They were just bulk crates of belts. This crate of belts was for power steering; this crate of belts was for non-power steering; this crate of belts was for 421 tri-power without power steering, due to the pulley sizes all being different.

She would look at the manifest that was taped to the side of the motor. There was one taped to each side of the motor on the tappet covers. It didn’t matter which side of the line you were working on, you could look at that one, and nobody would rip that off. I’ve seen cars come out of the back end running with the manifest still taped to the motor. Probably some of them reached the dealers and they’d take them off in prep. The first job that they did was the power steering bracket.

The next job, a little old lady – her husband was on the radiator line, a foreman, his name was Bruno. her name was Jenny -she put carburetors on. Whenever she got a tri-power to put carburetors on, she got behind, because she had three carburetors to install. There was an area right there that was probably forty feet long that was nothing but pallets of carburetors two deep. She would have to walk in among them and get the right part. She went by the manifest hangin’ on the side of the motor as to which carburetor that took.

Then there was a woman that worked right behind her. Her name was Liz. Her husband was the president of our local in the union. Her job was – I want to say she put fuel lines on. Then it turned the corner, and a kid from Brown City by the name of Pat Brady. He had an Iris Mist ’65 Chevy. He was a Chevy man. What was his job? I used to know all them jobs right by heart.

WAC: Where did the clutches get installed?

CP: They came out of Plant 9 with a damper plate on the automatics. The clutches were already on the flywheels when they came up. We didn’t have to put clutches on.

WAC: Bellhousings?

CP: Nope, we put bellhousings on at the motor bridge. I used to have a bench job building up the clutch forks. The little retainer ring that slipped over the ball, that was part of that bench job. You’d take the bellhousings, and you’d have a little foot-operated mechanical press, you took that clutch fork, put on that spring clip, put a rivet in it, set it on there, then stepped on the switch with your foot. It would round that rivet over.

Then you took the bellhousing and you screwed in that ball that had an allen head in it, you put the clutch fork through the side and hooked it on there, you put the rubber boot around it. Then that bellhousing was ready to go on the engine. You’d have stacks of bellhousings for different cars; big cars, Tempests, you know, different ones. That motor bridge would cover, all totaled, 150 feet.

Then it crossed over an aisle and the line went down and went maybe another 200 feet then it dropped down through the second floor. That’s where they mated the transmission to the engine. Then it went up and overhead and it dropped down next to the body line.

WAC: Did you work any other jobs?

CP: Other jobs I did at the plant… That was the last production job that I had. That was in ’69. Just prior to leaving the plant, I got off production and I went on sanitation. I picked up cardboard from the radiator line. I swept floors in the plant. On the weekends I would go in and clean out the spray booths.

The spray booth where they painted the hoods and fenders had a waterfall in it. They didn’t have big vacuum fans. The waterfall was more effective than anything. We’d clean the paint sludge out of the tanks and haul wagon-loads of that out.

I think to this day the most interesting job that I ever had at that plant was when I was on production for the first three or four months after every model year. You would work eight hours on the production line then you would go in the back end and work final repair. They’d ask you what you wanted to do. Well I’m not repairing cars. I’m not tearing dashboards out if I can be tearing out transmissions going over to Plant 16.

If they didn’t need anyone to drive, well, then you’d work repair. But they always needed drivers. You would take cars that had already been repaired from the back end of Plant 8, and you’d drive them from there over to Plant 16, which was about a half a mile away.

Plant 16 was where they put paint stripes on the cars, they washed them, and they rubbed them all down over there. They did anything final. They’d clean the interiors, put the plastic on the seats, they would put paper on the floors, cover the roofs of cars with vinyl tops or convertibles. They would get these cars ready to ship. The rail dock was right there, and there were guys that once the people got the cars ready to ship to the dealer, then they would drive them out to the rail dock, onto rail cars, or out into a parking lot across Josyln Blvd. If they went over there, they got loaded onto a car carrier. They were started up and driven by the people who drove the car carriers.

But the most interesting job was driving them cars out of the back end of Plant 8. And I never drove a big car unless it was a 2+2 or something like that. I would pick a GTO and hammer every one of them from the back end of Plant 8, down a half a mile of private blacktop where you didn’t have to worry about getting caught speeding. You’d stop ’em and power shift ’em. I got proficient at pounding transmissions because of doing that.

I mean when its not yours, you can really power shift. You learn to come out of the hole. You can set there and try coming out of the hole at four thousand. If you burn a set of tires, they’re not yours, you don’t worry about them. Not everybody did this. I was eighteen years old at the time. I enjoyed it. I did it because it was fun, because I was interested in the car. How does this one run? How does that one run?

That was just the highlight of my night to go back there and drive forty or fifty different GTOs every night, seven nights a week. And I hammered every one I ever drove. I don’t think I ever got in one and just drove it easy over to Plant 16.

They would bring you back in GMC Carryall vans, and they’d haul like eight or ten guys at a time back. You just got into another car and you did this all night long. Roughly every fifteen minutes you were making a trip across the back end of there, screaming another car.

WAC: So you were trying to catch the car in front of you all night long.

CP: Oh no. I’d always try to be first, so I didn’t have anybody to get in the way. You can’t be power-shifting second and third with somebody else in front of you. You were going to be running them over. If you sat by the door in the Carryall you jumped out and you went to the first Goat.

If you didn’t pick out a GTO, you went to the first thing that had a hood scoop on it, jumped in it and you were gone! Also by doing that, you got there quicker than anybody else and you could fool around over in Plant 16, go get a cup of coffee. You had four or five minutes before that Carryall was going to be there and if you were the last on into it, that meant you also were by the door and you could be the first one out.

WAC: The Carryall followed the last car over to Plant 16?

CP: Everyone would take off, and the Carryall would come behind everybody. By the time he got over there, everybody had already put their cars in the plant, and were walking back out the door to get into the van. It wasn’t a mad rush. You had guys fifty, sixty years old doing this. They didn’t care. They didn’t want to drive a GTO with a four-speed. They wanted to drive a big old Bonneville with an automatic, so it gave ’em a nice smooth ride over there.

WAC: You could set in the driver’s seat and think to yourself, Somebody’s gonna really enjoy the way this GTO runs.

CP: Yeah. This one really screams. This one doesn’t run so good. This is a GTO with an automatic on the column that runs faster than anything I drove this night. I don’t know why that motor would perform faster. I don’t know if it kept performing faster.

My own opinion, if you drive thirty or forty of ’em every night for four or five nights, you learn to tell the difference between them. Is this one fast? No. Is this one quick? You bet! One thing I did learn, in ’66 when they quit building the tri-powers, I thought that it wasn’t gonna be fun to drive the next model year. The quadrajets sounded relatively close to a tri-power. They made a lot of noise. They were basically as fast. You couldn’t tell the difference between a quadrajet, four-speed ’67 Goat, and a ’66 tri-power four-speed car.

WAC: How did the Ram Air cars run?

CP: Ram Air cars? I don’t remember driving Ram Air cars in ’66 in the plant. I know that they had ’em, I don’t remember driving ’em. I don’t even remember seeing them pans on them cars. If they put them on, it was in Plant 16 or someplace that I didn’t see them.

I don’t remember a ram air car in ’67 either. I remember people talking about them. There’s something special on this car. I remember ’69, which was the first year they had the little hood flutters that worked. That was the first year I remember seeing something under the hood.

At that time our opinion in the plant was that this is just something to attract the attention of the people. It gives the car fresh air. It doesn’t force air in. It doesn’t do anything; it just opens it up so it gets more air. The people in the plant, as an overall opinion, weren’t impressed with this. At that time I wasn’t too much impressed with what I called round-body cars, the ’68 and 69’s. I had already gotten rid of my GTOs. I was a family man by now, but I still loved to drive ’em down there.

The Ram Air IV cars in ’69 – every now and then you’d see the lettering on the hood that said RAM AIR IV – these cars hauled butt. I know that. They were fast!

Topics covered in part four:

- The 100% Rack

- Engine fire-up

- More motor bridge

- Pilferage

- Inspectors

Made in Pontiac PT3 2

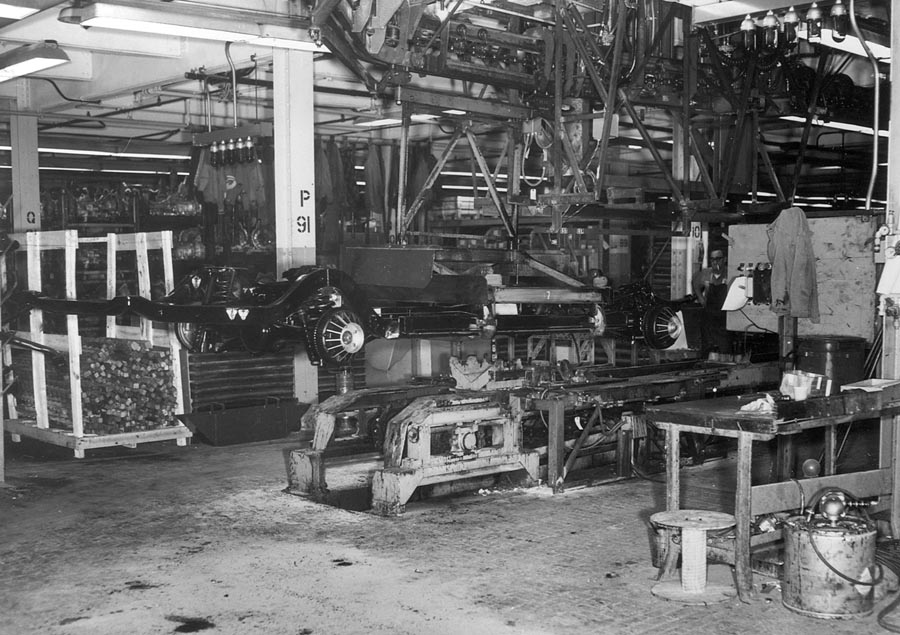

Built-up frame for a full-size car being dropped on assembly line one. Note blackout paint on rear shock absorbers and various other components. Also note 8-lug brake option.

Made in Pontiac PT3 3

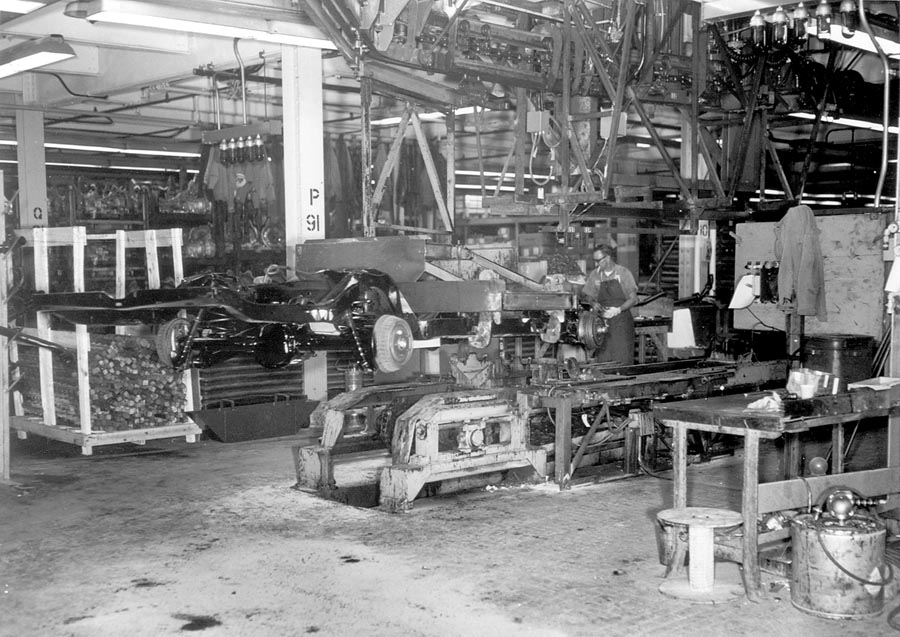

Another frame headed down line one. This one is meant for an A-body. Note unpainted drum brake assemblies.

Made in Pontiac PT3 4

A “Jitney” tractor headed back to plant 8 for another load of completed cars. Jitney totes two trailers of four cars each.

Made in Pontiac PT3 5

itney driver loads his own trailers with cars that did not require repairs in plant 8. Cars that were repaired were driven, not trailered, to plant 16.

Made in Pontiac PT3 6

Outside plant 16. Note GMC Carryall on right of photo. Carryalls ferried drivers from plant 16 back to plant 8.