The Nissan L series of automobile engines ranged from 1.3 L to 2.8 Liters in both I-4 and I-6 configurations and were produced from 1967 through 1986. This was the engine used in the Datsun 240Z sports car, the Datsun 510, and the first Nissan Maxima.

The design is often incorrectly attributed to Mercedes-Benz. In 1966 Prince Motor Company merged with Nissan. At the time of the merger, Prince had been previously licensed to produce copies of the M-B four- and six-cylinder engines. But by the time of the merger, the Prince Motor Company had refined the design to such a degree that it no longer needed licensing. The engine still resembles a Mercedes in many ways, particularly the valve train.

These engines are known for their reliability, durability, and parts interchangeability. It is a 2-valve-per-cylinder SOHC non-crossflow engine, with an iron block and an aluminum head.

The four-cylinder L series engines were replaced with the Z series and later the CA series, while the six-cylinder L series engines were replaced with the VG V6 series and RB DOHC series.

Cutaway of 1972-1976 Nissan L18 Engine

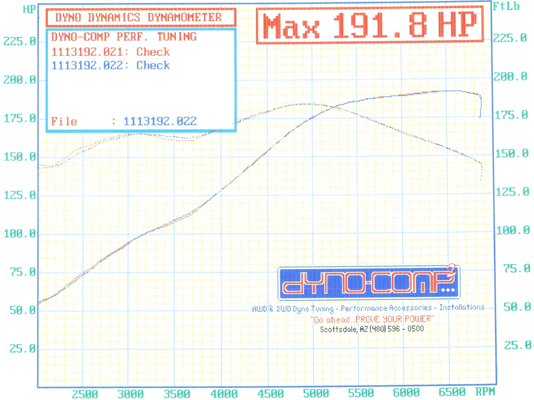

This is HybridZ Member Duragg’s posted setup as of Fall 2011 when he dynoed his ’73 240Z. This setup is a good example showing that a good setup with the right cam, combined with compression and a decent intake configuration can provide good street power, even from a 2.8-liter build.

240Z Years:

Duragg notes that he spent less than a grand building this motor and that the most expensive pieces were the cam and pistons.

HP: 191.8 @ 6600Torque: 185 ft/lbs @ 4900Block: L28 +1mm Overbore Cast ITM PistonsHead: N42 Work UnknownCompression: 10.3:1Cam: Isky L490Intake: Triples DCOE 40-151 @34 Choke

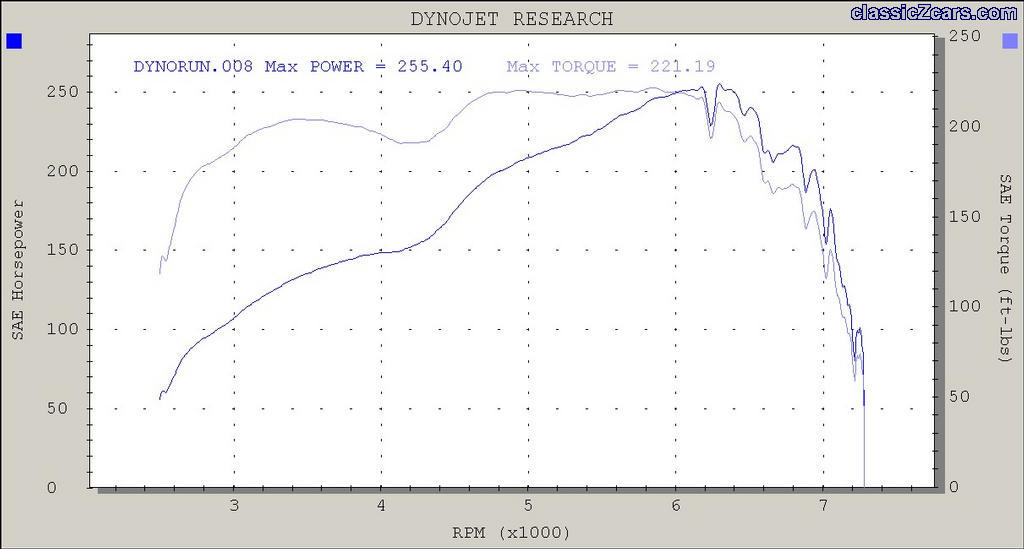

Dan Baldwin’s Build

Dan Baldwin and his engine have been stirring up the debate for many years now. Some haven’t seemed to have such luck when building a high-compression motor, yet builds like this show that it’s indeed possible.

-

- Block: L28 Bored out +3.5mm

- Crank: Diesel Maxima

- Rods: 240Z

- Pistons: KA24E

- Displacement: 3.1 Liters

- Head: N42 shaved .020″-.040″(exact unknown), 40.5cc chambers, porting & minor chamber shaping by Sunbelt Engines in Atlanta

- Cam: 310deg/.550″, custom grind by Sunbelt

- Compression: 11.6:1

- Intake: 3x2bbl 45mm OER Racing carburetors

- Fuel: 93 Octane

- Timing: 34-38 Degrees (no power difference claimed)

- Horsepower: 255 @ 6,200 RPM. Dyno breaks up past 6200 due to emergency use of 240Z points distributor, which was later replaced with a Pertronix Ignitor magnetic pickup. The car now pulls clean up to the 7200 RPM redline (and I’m sure makes a bit more than 255whp…).

- Torque: 221lbs @ 4700

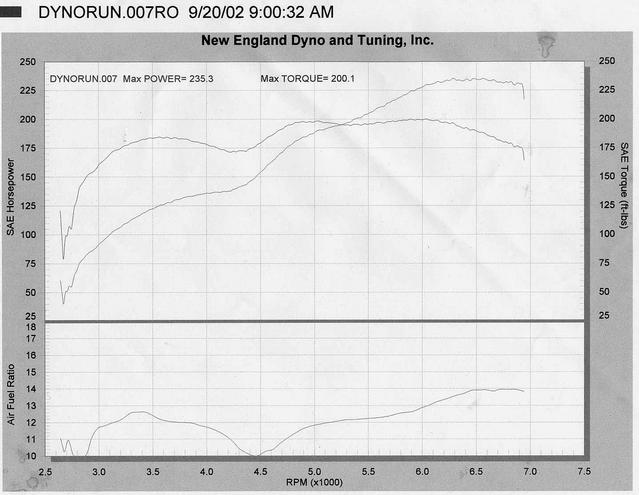

- Notes: In a previous version of the block with +3mm bore (versus +5 above) it displaced 3098cc versus its later 3133cc and made 235hp and 200lbs of torque with 10.6:1 compression. Both Dyno graphs are shown below.

3133cc Iteration

3098cc Iteration