Specifications for the Gen 2 and Gen 3 V-8 Engines

Block Specifications

The engines discussed here are the 1966 and later GEN-2 and GEN-3 engines, from 290 to 401 cubic inches. As previously stated, the GEN-2 and GEN-3 engines are separated in that the GEN-2 had a lower deck height (9.165″), and GEN-3 engines use a higher deck (9.208″) as measured from the crankshaft centerline to the top of the block deck where the cylinder head is bolted. This can be a problem with exchanging heads and manifolds as there were slight differences in the components in each generation, though with simple machining, they can be exchanged from block to block.

The major difference is not GEN-2 to GEN-3 but from the “small” to “big” block, though all blocks are all dimensionally the same size, except for the deck height. The 290-304-343-360 blocks use crankshafts having rod journal sizes of 2.09″ while 390 and 401 blocks use 2.248″ rod journals. Main bearing journals and bore centers (the distance, center-to-center, between each cylinder bore) on all AMC V8 engines are exactly the same at 2.747″ and 4.75″, respectively. (See Crankshaft and Connecting Rods, below).

Crankshaft and Connecting Rods

All AMC V-8 cranks have 2.747″ main journals. The 290-360 cranks are cast nodular iron units, while 390 and 401 cranks are forged steel – stronger than the cast pieces. In 1969, since the 290 blocks were used in Trans-Am, a special forged steel crankshaft, part number 4485728, was offered. This piece that fits the GEN-2 low-deck 290 and 343 engines as it has the short stroke arm. This crank is rare, but if you can find one, grab it.

Engines from 290 through the 360 use 2.090″ diameter rod journals. The 390 and 401 use 2.248″ diameter rod journals. The 290-360 rods have 0.931″ pin bores and pin lengths of 3.187″. All 290-360 rods are 5.875″ long, and they are all cast nodular iron, which means that they cannot accept as much stress as forged units. AMC did offer forged connecting rods for the 290 – 343, part #4485725. Sealed Power offers these rods under part #CR 1410. The 304 and 360 may also use this rod.

1968-1969 GEN-2 390 rods had a big end diameter of 2.248″ but were shorter in length at 5.790″ (forging #3143739) than the GEN-3 390/401 rods because of use in the low-deck GEN-2 block. GEN-2 390 rods have 1.00″ pin bores and 2.94″ pin length. GEN-3 high deck 390 (1970 only) and all 401 connecting rods use the same 2.248″ crank journal diameter, the same 1.00″ pin bores, and 2.94″ pin lengths, but have a rod center-to-center length of 5.858″ (forging #3197047). All 390-401 connecting rods, regardless of the year are forged steel and are excellent for performance work after resizing, Magnafluxing, shot-peening, and polishing.

Pistons

All stock AMC pistons were cast-aluminum. Since each series of GEN-2 and GEN-3 heads used the same combustion chamber size, different compression ratios for the different size engines were achieved by varying the size of in the piston dish on top. The factory did not produce oversized, extra-compression pistons for owner or dealer installation. However, there are some aftermarket selections (see Modifying the AMC GEN 2 and Gen 3 Engines).

Cylinder Heads

The 290 and 304 engines used smaller valves than the 343-401 engines, with 1.787″ intake and 1.406″ exhaust head diameters. This was to make sure that the valves were not shrouded by the smaller bore and to ensure the valves would not hit the block deck in the full open position. The 343 engines, the 1970 model 360, and the ’68-’69 390 had 2.02″ intakes and 1.625″ exhausts. The late 360 and 390, and all 401 blocks used the 2.02″ intakes but had larger 1.68″ exhaust valves fitted.

Manifold Interchangeability

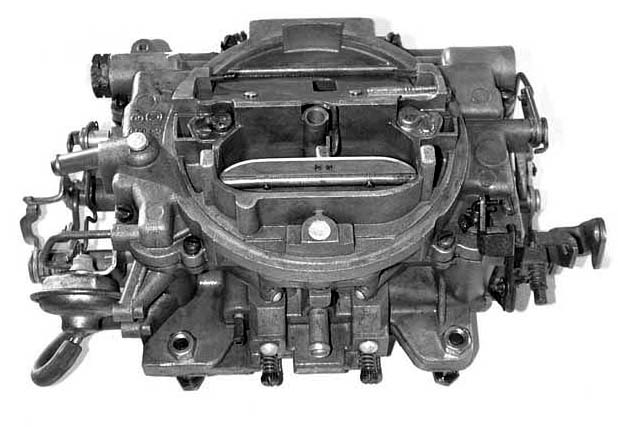

GEN-2 and GEN-3 engines used different-sized manifolds due to deck height differences that affected the distance across the block valley. All 1966-1969 intake manifolds will interchange with each other, since block, head castings and bolt patterns were all the same regardless of displacement. The 1970-1974 manifolds are all the same as well. Instant four-barrel upgrades can be made for those with a 2 bbl. car by merely replacing the manifold.

Using a GEN-2 Manifold on a GEN-3 block and vice versa cannot be done without modification also because the two center mounting bolt locations have been moved upward and inward on the GEN-3 piece. Further, the GEN-3 manifold contains more “meat” in the mounting surface because its higher deck moves the heads further away from the manifold center-line.

To mount a 1970 and later GEN-3 manifold on a 1966-1969 GEN-2 Block, the manifold should be planned to move the center line back to GEN-2 specs, AND the center bolt holes are elongated to bring them into alignment with the cylinder head. Conversely, to mount a GEN-2 manifold on a GEN-3 block, thicker manifold gaskets and the same elongation of the center manifold bolt holes will allow fitment. This is especially true if the early hi-performance factory manifolds (sold by the aftermarket) are selected for a GEN-3 Motor.