How to Cure Intermittent or Hard to Start Problems with the 1984-1996 C-4 Corvette

by Paul Langevin – Chevrolet and Corvette Advisor

One of the more frequent complaints I hear about is C-4 Corvettes that have difficulty or intermittent start problems.

If the dash lights up but it won’t turn over, or just clicks, take off the battery cables and clean the connections then reassemble, as the trouble is extremely common if the battery connections are not cleaned occasionally. The bad connection passes enough low amp current to light up the dash, but once the load increases it’s not able to supply the required current.

If the engine spins but won,t start, always drop back to the basics of compression, airflow in and exhaust out of the engine, ignition spark, strength and timing, and fuel delivery, volume and pressure oil pressure and temp cooling, temps, and fluid levels (fuel, oil, coolant) computer controls and sensors.

If you have not done a compression check and verified the valves are lashed correctly that’s a good place to look, but only after the basics of ignition timing, spark, strength, and fuel delivery are checked. Your fuel pressure regulator, or dirty injectors, or clogged fuel filters, or loose connectors on injectors and sensors, and ignition wires are frequently the cause. Other issues are corrosion on electrical connections, defective sensors, loose or broken vacuum lines.

I always check for steady fuel pressure and that the spark is consistent first and then verify the spark plug condition. I also check for vacuum leaks, and loose battery connections, and loose grounds.

These threads on my forum will further clarify this issue:

- http://forum.grumpysperformance.com/viewtopic.php?f=80&t=728viewtopic.php?f=70&t=202

- http://forum.grumpysperformance.com/viewtopic.php?f=32&t=168

- http://forum.grumpysperformance.com/viewtopic.php?f=32&t=596

- ttp://forum.grumpysperformance.com/viewtopic.php?f=32&t=3954

IMPORTANT: ALWAYS GET A FACTORY SHOP MANUAL BEFORE YOU START

- Verify fuel pressure by using a fuel pressure gauge on the Shrader valve on the fuel rail, with a pressure gauge.

- Verify injector pulse by using a noid light, & spark at the plugs by using a spark tester.

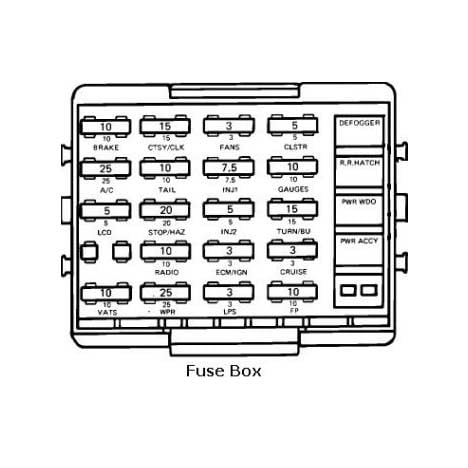

- Verify timing with a timing light. Pull the trouble codes and check all fuses.

These links contain illustrations that will help you understand the issues:

- http://forum.grumpysperformance.com/viewtopic.php?f=36&t=628&p=839#p839�

- http://forum.grumpysperformance.com/viewtopic.php?f=80&t=728&p=8392&hilit=codes_fuses#p8392

- http://forum.grumpysperformance.com/viewtopic.php?f=32&t=304

BEFORE you start going nuts look at the obvious stuff first!

- CHECK THAT YOUR IAC and TPS sensors are set and adjusted correctly.

- Set your ignition timing,

- Make sure there’s fuel in the gas tank, and

- There are no blown fuses and

- See if you have a STEADY 37-40 psi on the fuel rail.

- WHEN TESTING, be sure the fuel pressure gauge reads correctly by comparing it to a second test gauge, fuel pressure gauges are frequently defective.

Effective diagnosis and troubleshooting are to have a logical plan and to follow it without skipping any steps. Whenever you get into unexplained symptoms drop back to the basics. You should always have the FACTORY SHOP MANUAL TO INDICATE THE TESTS, NEEDED AND THE EXPECTED RESULTS LISTED.

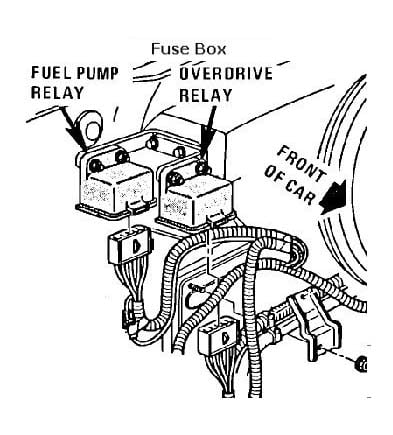

Get out a multimeter and verify every fuse is good, and that you have 13 volts at the battery and you’ve got at least a 1/2 tank of fresh fuel, before you start chasing your tail, thinking about more complicated problems. So the next step is to get out your multimeter and carefully verify that ALL YOUR FUSES AND RELAYS WORK.

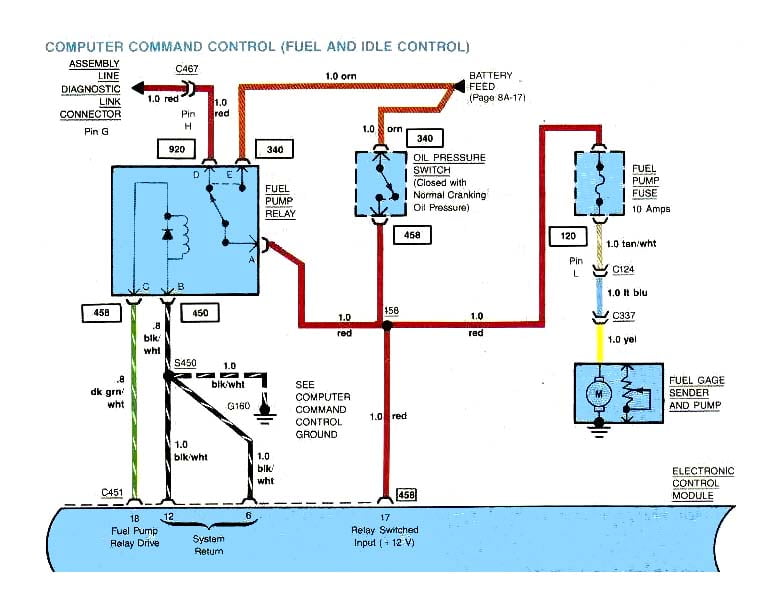

Given that you are having this problem it is very likely that they will not. Therefore next check the connections on the oil pressure sensor at the rear of the block next to the distributor. If they look OK, I would replace the oil pressure sensor itself, because the fuel pump will only continue to run after the first few seconds and you will not get voltage to the ignition if this sensor tells the CPU to have less than 5 PSI of oil pressure during the start-up process.

I have seen several Corvettes with similar start and then stall issues that cleared up after replacing those sensors. I’m reasonably sure that if the sensor INCORRECTLY and INTERMITTENTLY indicates that the oil pressure has dropped to zero, this will cause the problem. Replacing the sensor can cure the issue, and it is a good idea to install a new one anyway.

See the following threads/links that will add�more detail:

- L98 Engine Start Sequence: http://forum.grumpysperformance.com/viewtopic.php?f=32&t=1401&p=8895&hilit=start+sequence#p8895

- Corvette Trouble Codes http://forum.grumpysperformance.com/viewtopic.php?f=32&t=2697

- Testing an Ignition Coil: http://forum.grumpysperformance.com/viewtopic.php?f=70&t=270&p=1289#p1289

- Checking and replacement of the HEI Pick-up Coil: http://www.73-87.com/7387garage/drivetrain/pkupcoil.htm

- How Distributorless Ignition Systems Work: http://www.aa1car.com/library/dis.htm

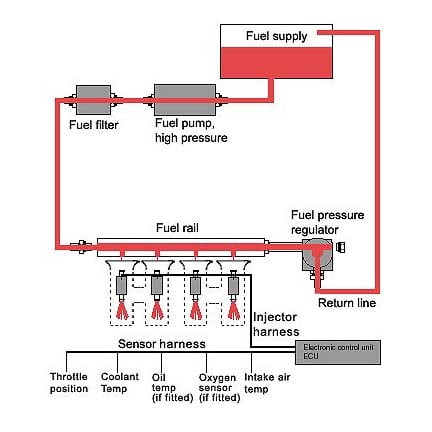

Next, verify your fuel pressure stays up in the 37-40 psi range without falling much after the cars shut off for at least 5 full minutes. If the fuel rail pressure does drop off in the first few minutes it’s almost always a leaky injector or bad fuel pressure regulator.

Check for vacuum leaks that could cause these symptoms. Remember that the fuel pressure should stay fairly consistent while the car is running, regardless of how fast or long the throttles quickly blipped or held wide open.

Be sure the throttle linkage and blades move smoothly and don,t bind or stick at any point in the movement arc. If you have an early year TPI, that is designed to use a 9th cold start injector, that is used to richen the f/a mix. Check it, as it is a potential problem source.

If your car won’t start easily on the first try but starts easily on the second or third attempt, that’s a common indication of either a leaking fuel pressure regulator (about 70% of the time), or less commonly a defective fuel pump (about 10%, of the time the pressures low or they leak internally) or it may be leaking injector(s) (about 20% of the time). But it can also be a partially clogged fuel filter, or rarely but possible, the air filter.

Start with testing the fuel pressure in the fuel rails, that symptom is frequently the result of

- DEFECTIVE fuel pressure regulator, or leaky injectors,or

- A blown fuse or the blown fuse-able link near the battery,

Get a fuel gauge, install it on the fuel rail – it should reach 40psi almost instantly when you try to start the car and maintain 40psi or more at the fuel rail for at least 15 minutes. Wet, loose, or broken electrical connectors or corrosion on connectors, are also possibly a cause of intermittent problems.

NOTE: To remove the connector from the injector, push carefully in the middle of the locking clip, with your thumb, This will make the sides, and tips move OUT WARD in their connector slots allowing the tips that hold the injector into the connector to slide out of the way from the injector body, and you can then pull the sides away. WATCH the locking clip – IT can and WILL come off and get lost, if your not carefull.

I’ve generally found no starting or running problem with any Corvette LT1 or TPI EFI if it will quickly build a minimum of 38-40 PSI on start-up and MAINTAIN at LEAST 38-40 psi for a MINIMUM of 10 minutes after the engines turned off, 40-42 lbs is what the factory says is appropriate. So if you are getting 38-40psi your pressure readings are normal.

It is possible that that the TPI has a defective injector that’s leaking or not flowing fuel, or is partly clogged. You can test this, to a degree, with a fuel pressure gauge. Install a fuel pressure gauge on the fuel rail, and turn on the ignition key. Watch the gauge; it should jump to 37-42 psi then remain fairly steady for at least 5 minutes before gradually losing pressure.

If you can – and this is a pain to do – temporarily remove the injectors. Leave them on the rail, but remove the rail. from the intake itself, This requires removing the majority of the TPI. Here is how to do that: http://www.thirdgen.org/injectorswap. Remove the rail, but leave it connected to the fuel lines.

Then put a strip of cardboard under each bank and have a buddy turn the ignition key on but DO NOT try to start the engine. You should hear the fuel pump run for 3 seconds while you look to see what happens. You should get an immediate spray of fuel.(all should be about equal and no injector remains dripping fuel). Turn off the key, and watch closely to see which injectors (if any) are leaking.

If all is well, verify that the TDC on the damper and the timing tab, are correct, and you’ve set the ignition timing correctly. Set the IAC and TPS sensor and check for vacuum leaks, verify the voltage, at the battery both running and before you start the car, it should be over 13 volts running and over 12.5 volts on just the battery.

Verify the plug gap is at about .045 inches (1.15mm) and the plugs are burning correctly and set your ignition timing at 6 BTDC at about a 700-750rpm idle. Then use the timing light to verify the ignition advances as the RPMs are increased. If it’s not advancing smoothly, the distributor might need work or the CPU might be defective.

Download my checklist – see the list in the gray box at the left.

Have more questions? Visit my website at http://www.grumpysperformance.com/

Click on the Images Below to Enlarge

Click on the button below to view the No Start Checklist.

See these 4 pages on Fuel System Diagnostic from the service manual.